Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Anhui Hausen Food Machinery Co., Ltd

|

Accessories for compact spinning Machines

|

|

|

|

|

DX-series starch washing cyclone is used for refining and washing starch milk, mainly for removal of soluble and insoluble gluten, fine fiber and other impurities in order to purify starch.Adoption of cyclone for refining and washing starch milk will bring along the advantages of high efficiency, high automation, good product quality, reliable operation and convenient maintenance.

Specifications

1. starch recycling cyclone

2. Widely used for starch extraction in starch processing plants.

3. ISO 9001starch recycling cyclone main features

Fully stainless steel to be sure these is no corrosion;

Advanced surface treatment craft. Oil and dirty resisting.

Widely used for starch extraction in starch processing plants.

It has multifunction of concentration, recover, washing and separation for hydrocyclone.

Cyclone pipes are made from material of reinforced nylon with high strength, better abrasive resistance and excellent separation result.

Hydrocyclone designing is adopted to get better starch separation according to the features of different material.

Pipeline of hydrocyclone group passes computer optimization design. Compact and elegant.

Special sealing design, friendly operation.

|

|

|

Anhui Hausen Food Machinery Co., Ltd

|

Accessories for compact spinning Machines

|

|

|

|

|

A typical hydrocyclone Starch Washing System consists of batteries of cyclones in completely unitized and enclosed housings, arranged for efficient counter current washing. The centrifugal forces needed to make the Separation are derived from energy supplied by pumps. The high rotational velocities in the individual cyclones cause the starch to concentrate in the underflow while the suspended gluten follows the overflow wash water stream. The multistage systems provide easy and precise control of the process, resulting in the uniform, high quality starch required in today highly demanding marketplace.

Applications:

Starch washing, refining and protein separation

Starch concentration

A-starch and B-starch separation

A-starch, B-starch and gluten separation (Hydrocyclone method)

Starch recovery

|

|

|

Anhui Hausen Food Machinery Co., Ltd

|

Accessories for compact spinning Machines

|

|

|

|

|

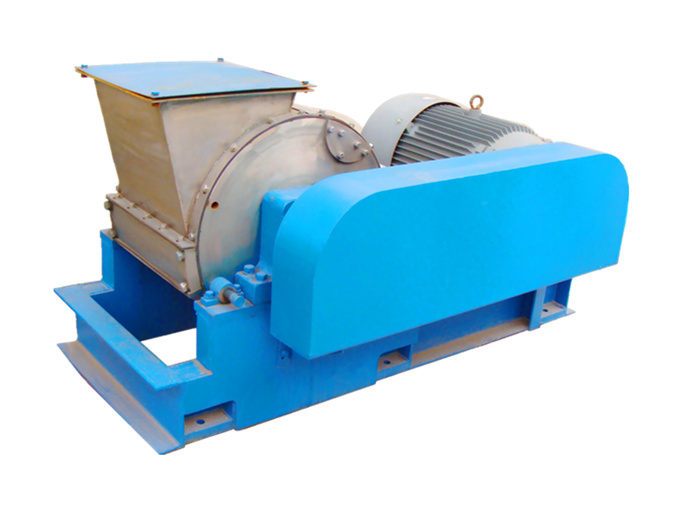

The company's CMJ-400/500/600/840 type rasping machine is widely used in potato starch processing industry, to rasp and break the potato material. The machine is all stainless steel, the rotor is forged and processed by special stainless steel, and hundreds of the specially designed, 1.25mm thick, two-way combined rasp are installed on the rotor. The rasp is between the two cone-shaped plywoods, and fixed by the pins, inserted in the tapered grooves of the rotor, for quick replacement. The machine combines the good points of domestic and foreign products, novel design, compact structure, high speed (rotor line speed of about 100 m / s, that is, the relative speed of 1400-2200 r / min), the material rasp fine, grains smooth, high starch free rate, and extraction rate. Structure and principles Rasping machine is the composition of the base, casing, rotor, spindle, feed, two-way combination of rasp, bearings, bearing, fixed block, sieve plate, motor, V-belt pulley, protective cover. Uses: used for the crushing and breaking of a variety of potato raw material

|

|

|

Anhui Hausen Food Machinery Co., Ltd

|

Accessories for compact spinning Machines

|

|

|

|

|

Overview: YT-LXS centrifugal sieve is our leading products in recent years, the product is improved and designed on the base of our company's foreign and domestic old products, technology leader, currently at the forefront in domestic sales, receiving good results from the new and old customers. It is mainly applied to starch of potato and sweet potato etc, and other food and chemical industries. Features: The whole machine adopts horizontal structure, the main flow passage components of 304 stainless steel, the sieve of conical structure and by the high-precision dynamic balance verification, using high- transmission parts, equipped with the company's high-efficiency slurry pump and sub-screen pump, smooth rotation at work, operation continuous and easy, slurry separation high-efficiency, good sealing effect, is an ideal slurry separation equipment in the currently potato starch industry.Performance parameters: with screen mesh to 60 mesh, 80 mesh, 100 mesh. Purposes: to remove the larger impurities in starch.

|

|

|

Anhui Hausen Food Machinery Co., Ltd

|

Accessories for compact spinning Machines

|

|

|

|

|

Overview: TSJ-dewatering machine is our main products in recent years, the product is improved and designed on the company's foreign and domestic old products, replacing the centrifugal scraper centrifuge, now at the forefront in domestic sales, receiving very good effect from old and new customers. It is mainly applied to starch industry, other food and chemical industries. Features: The whole machine adopts horizontal structure, the main flow passage components of 304 stainless steel, using high-precision transmission parts, equipped with the SK-type vacuum pump produced by our company, rotating smooth at work, operation continuous and convenient, good sealing effect, high-efficiency dehydration, is an ideal starch dewatering equipment in the domestic starch industry.

|