Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Anhui Hausen Food Machinery Co., Ltd

|

Accessories for compact spinning Machines

|

|

|

|

|

Jet the liquefier new high-pressure steam jet liquefaction of high-pressure steam in the steam supply pressure is bigger than 0.6Mpa steam pressure jet of high-strength micro-turbulence can form in the liquefaction process, starch dispersion, liquefied completely. Feed pump head requirements low, low energy consumption. Saccharified liquid of high purity, no insoluble starch granules, protein condensation effect, and the starch and protein separation and Jet liquefaction, the protein was significantly together and float on the liquid surface, greatly accelerate the speed of sugar filtration. Eliminate the gap saccharification and liquefaction caused by the uneven heating of the liquid material to the end there dextrin phenomenon, changing the protein is difficult to solidification, sugar filtration difficulties, proteins, dextrin class mixed with the sugar in, resulting in fermentation when the bubble an increase in serious escape liquid, the extraction rate after the procedure and the quality of the refined liquid differences in production conditions. Jet liquefaction continuous, plug the new high-pressure steam jet liquefier from the structure of the principle of complete elimination of the clogging phenomenon in the starch in whole meters, or play powder concentration is bigger than 25Be produced a blockage from each manufacturers to use the situation to see, within two years of the jet liquefier to clean up without disassembly.

|

|

|

Anhui Hausen Food Machinery Co., Ltd

|

Accessories for compact spinning Machines

|

|

|

|

|

Low-pressure steam jet liquefaction liquefaction effect of new low-pressure spray liquefaction in liquefaction process can form high-strength micro-turbulence, starch dispersion effect, zero hour mashing, no insoluble starch granules, protein condensation effect and the starch and protein separation effect . By injection, the protein was together, floating on the liquid surface, greatly accelerated the rate of sugar filtration. Eliminate the gap liquefied fluid material as uneven heating caused by the end of a dextrin saccharification shortcomings. Difficult to change the coagulation of protein, sugar filtration difficult, and proteins, dextrin class mixed in sugar, resulting in fermentation bubble increased fluid escape serious impact on the extraction rate after the procedure and the quality difference between the production of refined liquid state. Low-pressure jet liquefier from the structure to completely eliminate the principle of clogging in the starch in whole grain rice or starch concentration is bigger than 25Be in the case, can not produce blocked from using the manufacturer's point of view, the use of 1 - less than 3 years without removing spray liquefaction clean, eliminating the last domestic jet nozzle aperture liquefier as other reasons, especially the use of superheated steam jet, frequently blocked the production of defects can not be continuous. The new low-pressure injection device used to feed with a liquefied gas way, driving force for the liquid, not only for low pressure steam, but also suitable for liquid jet of superheated steam at 105 degree the following spray liquid, the vapor pressure can only 0.1Mpa meet the needs of liquefaction and steam balance, vapor-liquid mixing, compared with the traditional method of liquefaction, steam savings of 15% or more. The film can be used to model spray liquefaction temperature control valve to perform the automatic control.

|

|

|

Anhui Hausen Food Machinery Co., Ltd

|

Accessories for compact spinning Machines

|

|

|

|

|

1. Raw material reception unitThe unit is the first step of potato starch processing. The main purpose of this unit is to preliminary remove impurity and put them into storage pool.

When unloading potatoes, it is better to use special shovels to prevent the potatoes from damaging. Potato storage time can't exceed half a month. The longer the potatoes are stored, the more adverse for the starch production.

Attention must be taken that potatoes should not be damaged at time of purchase. Damaged potato is perishable, and the rotten potato will affect the potatoes around easily. The quality of potatoes has very big influence on the quality of potato starch.

2. Hydraulic transport unitThe main purpose of this unit is to convey potatoes of the potato storage tank into conveying screw elevator and conveyor by flow conveying, and then convey them to a de-stoner through a flow trough. In the process of conveying, potatoes continuously roll and clash in stream flow to peel off sticky mud of potato, it plays a very good cleaning effect.

|

|

|

Anhui Hausen Food Machinery Co., Ltd

|

Accessories for compact spinning Machines

|

|

|

|

|

1. Raw material receiving unit Material receiving unit is the first link of cassava starch processing. The primary purpose of this unit is the cassava preliminary removing impurity and the smooth storing in inside of raw material storage tank.

Cassava is conveyed to the cassava yard after weighing by wagon balance, and then is conveyed into the cassava storage hopper by forklift.

The key of this unit is to remove sand and other impurities of cassava during the harvest, the sand stick to the cassava can drop through the vibrating screen. Preliminary de-sanding and removing impurity can relieve machine burden of de-stoning and cleaning unit.

Attention must be taken that cassava should not be damaged in cassava purchase.Damaged cassava is easily decayed, and decayed cassava is vulnerable to infect around cassava. Bad cassava material has a big influence to starch quality.

2. Raw material conveying unit

Cassava stored in the cassava hopper is conveyed to the large inclination-angle belt conveyor through conveying belt at the bottom of the hopper, and further is conveyed into cleaner to remove impurities by the large inclination-angle belt conveyor, removing sand and other impurities mixed in the materials at harvest time.

|

|

|

Anhui Hausen Food Machinery Co., Ltd

|

Accessories for compact spinning Machines

|

|

|

|

|

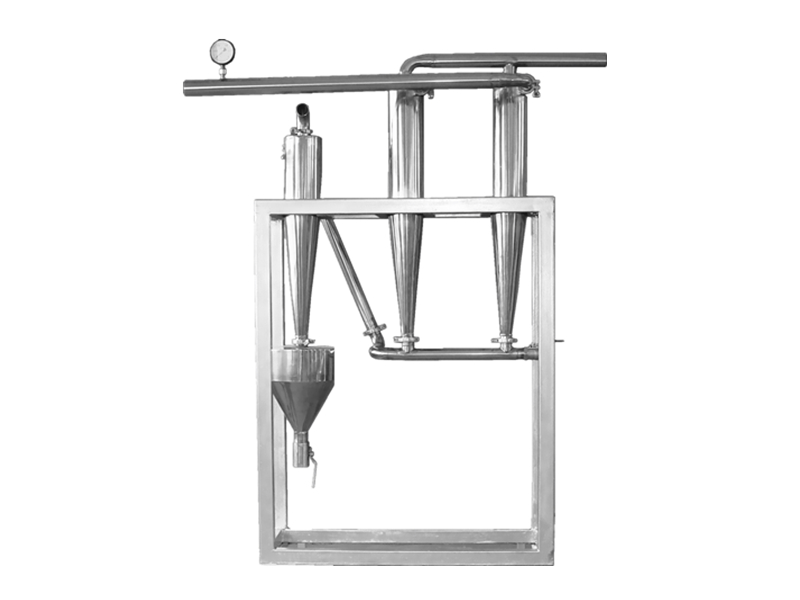

Uses: It is mainly used to remove sediment and impurities such as metals in the starch processing, and also applicable to remove impurities in other fluids, receiving good effect from new and old customers. Mainly suitable for starch industry and other food and chemical industries.

Features: machine with vertical structure, the main flow passage components of high quality 304 stainless steel, the device is simple in structure, advanced design, easy installation, high efficiency in cleaning, is an ideal sand removing device in the domestic starch industry.

|