Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Zhengzhou Anji Plastic Machinery Manufactory

|

Accessories for compact spinning Machines

|

|

|

|

|

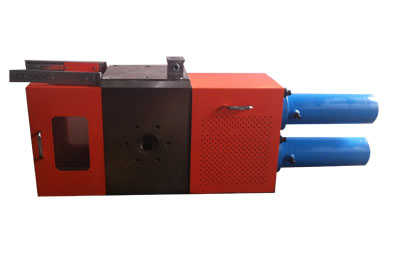

Double-piston continuous screen changer realizes a non-stopping screen changing operation by altering two pistons with double filtering areas. During production, the polymer melt is divided into two flow channels inside the screen changer housing, then conveyed through the two filters equipped with the appropriate filter medium. This filter medium consists of screen packs supported by breaker plates.

Features

It can match with extruders of different design. It is applicable to process with most polymers at high output.

Double-channel nonstop screen changer work alternatively, which can change the screen with minimum melt pressure fluctuating and production interrupting.

Two stages air vent for the hydraulic system to eliminate bubbling in polymer flow.

Superior sealing system completely eliminates polymer leakage.

External safety cover gives better appearance and safe protection.

It is equipped with circular、elongated or U- shaped screens, for enlarged filtration area.

Benefits

Eliminates line shutdown thus increasing production

Leakage-free process

Two breaker plates design increases filtration area compared to single breaker plate design

Reduced downtime & scrap

Reduced inlet pressure at extrusion die

Reduced temperature variations in the melt

|

|

|

Vipeak heavy Industry

|

Accessories for compact spinning Machines

|

|

|

|

|

At current, with further penetration of the economic globalization process, the economy in China develops swiftly and violently, the urbanization process constantly speeds up, the infrastructure construction makes great breakthroughs and all kinds of project construction like highway, railway, water conservancy projects and low-income housing have been growing vigorously, which promote the further development of the economy, but at the same time, lead to shortage of all kinds of resources such as natural sand and stone aggregates. Under such condition, the mining machinery manufacturing industry welcomes new development opportunity and the development has been unusually hot. |

|

|

Anhui Hausen Food Machinery Co., Ltd

|

Accessories for compact spinning Machines

|

|

|

|

|

Potato starch processing and manufacturing technologies

1. Stone extractor

2. Wash potato machine

3. transportation equipment (feeding spiral)

4. breaking equipment (rasping machine)

5. slurry and residue separation equipment (centrifugal sieve)

6. grit removal equipment (desander)

7. Starch hydrocyclone washing machine

8. Vacuum Dehydrator

9. air dryer equipment

10. Vibrating Screen

11. packaging

|

|

|

CROP TECHNOLOGY GROUP

|

Accessories for compact spinning Machines

|

|

|

|

|

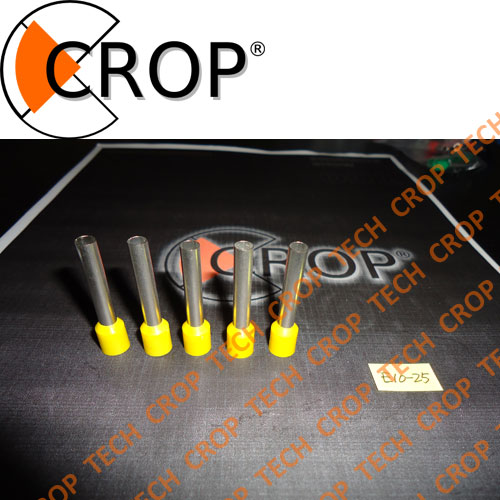

Ferrules ensure reliable electrical connections when terminating stranded flexible wires in terminal blocks, circuit breakers or other control devices. They prevent fraying and breaking of individual wire strands. Ferrules are available uninsulated and insulated with color coded plastic sleeves for single or dual wire applications. Insulated ferrules also support the conductor, preventing breakage due to bending, wire stress and vibration.

Ferrules are the preferred alternative to twisting wire strands or tinning the wire end. European Electrical Standards such as EN60204-1, and VDE 0611, specify that "Means of retaining conductor strands shall be provided when terminating conductors at devices or terminals which are not equipped with this facility. Solder shall not be used for this purpose." Conductors with tinned ends should not be terminated in compression clamps because solder will cold flow under pressure and eventually result in poor or loose connections.

Because ferrules are mechanically crimped onto wire ends, it is important to use the proper crimping tool to insure an efficient connection. We have a wide range of crimping tools available to meet your ferrule and application needs.

Choose from the following Altech Ferrules:

Insulated Ferrules - Industry Standard Colors

Insulated Ferrules - DIN Standard Colors

Uninsulated Ferrules

Dual Wire Insulated Ferrules

Insulated Ferrule Assortment Boxes

|

|

|

CROP TECHNOLOGY GROUP

|

Accessories for compact spinning Machines

|

|

|

|

|

Terminal block is designed to be used for connecting and disconnecting the electric circuit. The most

commonly used in low voltage splitting boxes, as shown below. The product has a bottom bracket for

DIN rail, the side screws used for fixation of input or output wires. Inner bolts can be used to connect

surrounding terminal blocks, or may remain empty.

PRODUCT RANGE:

Conductor :RE/RM smaller or equal 6mm Cu/Al.

USED MATERIALS:

Fireproof plasic PA66, brass, steel EN11383 with chromatized coating by EN12329.

PACKING:

Coarton dimensions: 45x37x33

Contain: 1200pcs.

Each: 24 g.

Netto: 28,9kg.

Brutto: 29.4Kg.

PACKING OF TERMINAL BLOCK ACESSORIES:

Contain: Depend on individual customer need’s.

STORAGE AND TRANSPORT:

Product do not have any specific requirements on storage. It is fire-resistant and it is not dangerous

|