Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

SKG Enterprises

|

Accessories for compact spinning Machines

|

|

|

|

|

Sprockets in simplex and multiple strands

|

|

|

SKG Enterprises

|

Accessories for compact spinning Machines

|

|

|

|

|

Roller Chains,PIV Chains,Conveyor Chains,Link Chains and Sprockets

|

|

|

SKG Enterprises

|

Accessories for compact spinning Machines

|

|

|

|

|

PIV Chains for Gear Boxes

|

|

|

RBC Bearings Pvt Ltd - SKF Authorised Industrial Distributor

|

Accessories for compact spinning Machines

|

|

|

|

|

Sub.: Supply of SKF Bearings and Accessories.

We introduce ourselves as one of the leading Authorised Industrial Distributor of world famous SKF Bearings. We stock a large variety of bearings of different types and sizes of bearings to suit your application.

In recent times, the excellence of SKF products and sophistication in up to date technique with a guaranteed service, extraordinary maintenance, has reached an all time high and image of SKF bearings is reigning supreme.

The only thing we can promise is performance and customer satisfaction.

|

|

|

Zhengzhou Anji Plastic Machinery Manufactory

|

Accessories for compact spinning Machines

|

|

|

|

|

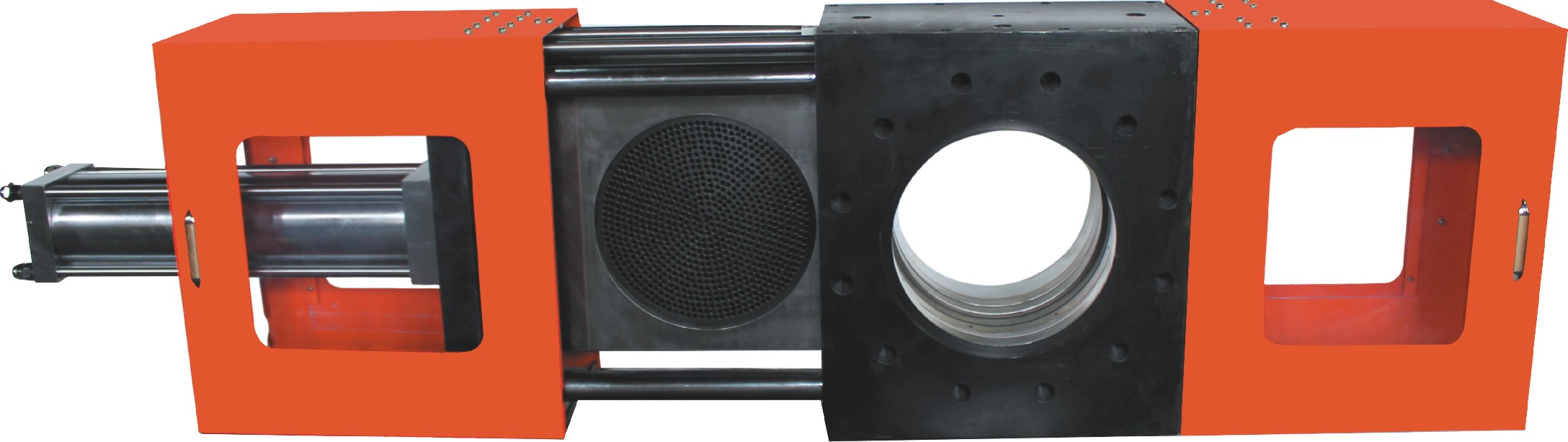

This series of screen changer consists of main body, slide plate, heater and hydraulic unit with

accumulator. It is driven by hydraulic power, and the slide plate carries 2 pieces breaker plates

can move linearly in both directions to achieve screen changing in a short time.

Features

Anji

patented technology on the sealing system design. Automatic compensation on sealing gap can be

realized during screen changing process. Compatible with extruders for various polymers processing

at high output.

Filtration area ranges from ï¿ 30-ï¿ 360mm.

With highly precise design,

the screen has good abrasive resistant, high pressure performance, ensuring large effective

filtration area and improving filtration effect. It works well even under high temperature up to 300

℃ and high pressure up to 50 MPa.

Screen changing time ≤ 2 seconds with pressure

accumulator.

Benefits

leak-free process

Minimum pressure drop

Improved products quality

Reduced waste materials

Reduced downtime & scrap

Reduced inlet pressure at extrusion die

Reduced temperature variations in the melt.

|