Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

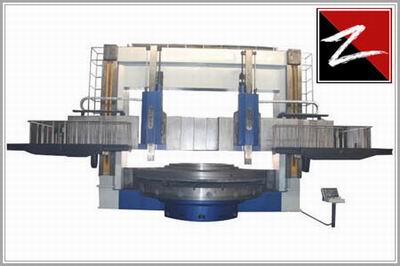

DVTCK5263 CNC Double Column Vertical Lathe in china

CNC Double Column Vertical Lathe

1. The most advanced production technology of vertical lathe, modularization design and analysis of infinite elements are adopted to integrate machine, electricity and hydraulics the advanced technology, which represents high-precision exquisite cutting. 2. Siemens 802DSL or Siemens 802C CNC system which owns 100% full manual switch and operation function, that means no programming is needed even for the common operator. Manual operation is convenient and practical. 3. Two-step machinery variable speed+ ultra-large torque DC motor stepless speed control to realize turning with constant line rate. 4. Excellent casting (HT300) is handled by heat aging. 5. The guide on the beam is embedded with chromium-masurium-manganese guide plate. 6. The left tool holder adopts the common type while the right one utilizes CNC system; both of the two tool holders can all be selected as CNC mode. 7. The guide of working platform adopts constant current oil supply with constant current motor with the feature of stable precision; the hydraulic oil utilizes refrigerator for constant-temperature cooling and reducing the variant quantity of the working platform. 8. Different lubrication parts adopt automatic lubrication pump for automatic timing and quantitative oil supply. 9. High-precision ball screw adopts imported bearing (Germany INA) for supporting. 10. JB/T9934.1-1999 precision inspection of CNC vertical lathe is performed JB/T9934.2-1999 technical specification of CNC vertical lathe 11. Lots of imported parts (electrical, servo motor, servo drive, hydraulic parts, bearings, screw, planetary reducer, etc.), reliable quality assurance. 12. Gear box adopts high-accuracy grinding gears. 13. With beams stainless steel protective and walking board etc.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

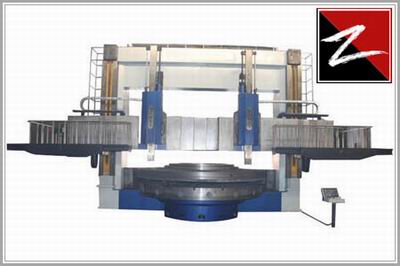

DVTCK5240 Double Column CNC Lathes

1. The most advanced production technology of CNC lathe machine , modularization design and analysis of infinite elements are adopted to integrate machine, electricity and hydraulics the advanced technology, which represents high-precision exquisite cutting. 2. Siemens 802DSL or Siemens 802C CNC system which owns 100% full manual switch and operation function, that means no programming is needed even for the common operator. Manual operation is convenient and practical. 3. Two-step machinery variable speed+ ultra-large torque DC motor stepless speed control to realize turning with constant line rate. 4. Excellent casting (HT300) is handled by heat aging. 5. The guide on the beam is embedded with chromium-masurium-manganese guide plate. 6. The left tool holder adopts the common type while the right one utilizes CNC system; both of the two tool holders can all be selected as CNC mode. 7. The guide of working platform adopts constant current oil supply with constant current motor with the feature of stable precision; the hydraulic oil utilizes refrigerator for constant-temperature cooling and reducing the variant quantity of the working platform. 8. Different lubrication parts adopt automatic lubrication pump for automatic timing and quantitative oil supply. 9. High-precision ball screw adopts imported bearing (Germany INA) for supporting. 10. JB/T9934.1-1999 precision inspection of CNC vertical lathe is performed JB/T9934.2-1999 technical specification of CNCvertical lathe 11. Lots of imported parts (electrical, servo motor, servo drive, hydraulic parts, bearings, screw, planetary reducer, etc.), reliable quality assurance. 12. Gear box adopts high-accuracy grinding gears. 13. With beams stainless steel protective and walking board etc.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

CXK125 CNC vertical turning center

CNC Vertical Turning and Milling Center

The CXK series CNC Vertical Turning and Milling Center was developed by our company, it is a new type turning and milling center with new functions, high precision and high efficiency. The machine is widely used in aerospace, shipbuilding, nuclear power, high speed railway, etc

CXK series CNC vertical turning and milling center have the functions same as general CNC vertical. All process except undersurface can be finished with one time clamping, such as turning, milling, boring, tapping, etc. Many kinds of more complicated curved surfaces, such as vane, can be also conducted with, if double swing milling head is set up. It has x and z axis, c three CNC for triaxial linkage.

The main components and main transmission adopts thermal symmetrical structure, with high thermal stability.

Worktable main shaft adopts high-precision double row cylindrical roller

bearing for centering in radial direction, and adopts large ball thrust bearing for loading in axial direction. Worktable is provided with the functions of precision indexing and turning and milling feedings.

The beam has hierarchical positioning function.

The ram adopts high-precision ball screw transmission. Machine is setup

with ATC with12-20 tool station.

Siemens 840DSL system (user can appoint other system) is adopted;

servo motor and servo driver all utilize Siemens products.

All the castings are made of HT300 gray cast iron (ram is made of ductileiron) which is treated with artificial heat aging, high-quality processing and improved assembly process. All the electrical parts, bearings, key parts, hydraulic parts were picked from the manufacturers with world famous brand.

Complete fitting configuration allows the user to put into operation only by preparing cutting tool and measuring tool. Perfect after-sale service, two years guarantee.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

CXK160 CNC vertical turning center

CNC Vertical Turning and Milling Center

The CXK series CNC Vertical Turning and Milling Center was developed by our company, it is a new type turning and milling center with new functions, high precision and high efficiency. The machine is widely used in aerospace, shipbuilding, nuclear power, high speed railway, etc

CXK series CNC vertical turning and milling center have the functions same as general CNC vertical. All process except undersurface can be finished with one time clamping, such as turning, milling, boring, tapping, etc. Many kinds of more complicated curved surfaces, such as vane, can be also conducted with, if double swing milling head is set up. It has x and z axis, c three CNC for triaxial linkage.

The main components and main transmission adopts thermal symmetrical structure, with high thermal stability.

Worktable main shaft adopts high-precision double row cylindrical roller

bearing for centering in radial direction, and adopts large ball thrust bearing for loading in axial direction. Worktable is provided with the functions of precision indexing and turning and milling feedings.

The beam has hierarchical positioning function.

The ram adopts high-precision ball screw transmission. Machine is setup

with ATC with12-20 tool station.

Siemens 840DSL system (user can appoint other system) is adopted;

servo motor and servo driver all utilize Siemens products.

All the castings are made of HT300 gray cast iron (ram is made of ductileiron) which is treated with artificial heat aging, high-quality processing and improved assembly process. All the electrical parts, bearings, key parts, hydraulic parts were picked from the manufacturers with world famous brand.

Complete fitting configuration allows the user to put into operation only by preparing cutting tool and measuring tool. Perfect after-sale service, two years guarantee.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

CXK200 CNC turning center

CNC Vertical Turning and Milling Center

The CXK series CNC Vertical Turning and Milling Center was developed by our company, it is a new type turning and milling center with new functions, high precision and high efficiency. The machine is widely used in aerospace, shipbuilding, nuclear power, high speed railway, etc

CXK series CNC vertical turning and milling center have the functions same as general CNC vertical. All process except undersurface can be finished with one time clamping, such as turning, milling, boring, tapping, etc. Many kinds of more complicated curved surfaces, such as vane, can be also conducted with, if double swing milling head is set up. It has x and z axis, c three CNC for triaxial linkage.

The main components and main transmission adopts thermal symmetrical structure, with high thermal stability.

Worktable main shaft adopts high-precision double row cylindrical roller

bearing for centering in radial direction, and adopts large ball thrust bearing for loading in axial direction. Worktable is provided with the functions of precision indexing and turning and milling feedings.

The beam has hierarchical positioning function.

The ram adopts high-precision ball screw transmission. Machine is setup

with ATC with12-20 tool station.

Siemens 840DSL system (user can appoint other system) is adopted;

servo motor and servo driver all utilize Siemens products.

All the castings are made of HT300 gray cast iron (ram is made of ductileiron) which is treated with artificial heat aging, high-quality processing and improved assembly process. All the electrical parts, bearings, key parts, hydraulic parts were picked from the manufacturers with world famous brand.

Complete fitting configuration allows the user to put into operation only by preparing cutting tool and measuring tool. Perfect after-sale service, two years guarantee.

|