Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

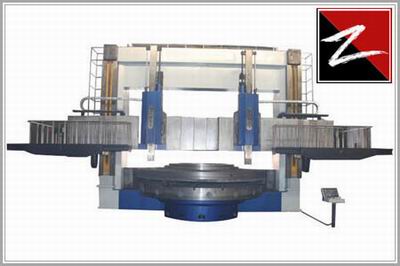

CK5225E Double Column CNC Vertical Lathe

CNC Double Column Vertical Lathe

CNC Double Column Vertical Lathe adopt the most advanced production technology, modularization design and analysis of infinite elements are adopted to integrate machine, electricity and hydraulics the advanced technology, which represents high-precision exquisite cutting.

Siemens 802DSL or Siemens 802C CNC system which owns 100% full manual switch and operation function, that means no programming is needed even for the common operator. Manual operation is convenient and practical. Two-step machinery variable speed and ultra-large torque DC motor stepless speed control to realize turning with constant line rate.

Premiumcasting (HT300) is handled by heat aging. The guide on the beam is embedded with chromium-masurium-manganese guide plate.

The left too holder adopts the common type while the right one utilizes CNC system; both of the two tool holders can all be selected as CNC mode. The guide of working platform adopts constant current oil supply with constant current motor with the feature of stable precision; The hydraulic oil utilizes refrigerator for constant-temperature cooling and reducing the variant quantity of the working platform.

Different lubrication parts adopt automatic lubrication pump for automatic timing and quantitative oil supply. High precision ball screw adopts imported bearing (Germany INA) for supporting.

JB/T9934.1-1999 precision inspection of CNC vertical lathe is performed. JB/T9934.2-1999 technical specification of CNC vertical lathe.

Best after-sale service (pre-sale, sale, after-sale, installation, debugging, training and guarantee)

Machine tool adopt lots of imported parts (electrical, servo motor, servo drive, hydraulic parts, bearings, screw, planetary reducer, etc.), reliable quality assurance .

Gear box adopts high accuracy grinding gears. With beams stainless steel protective and walking board etc.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

CKG160 CNC high-speed vertical turning lathes

High-speed CNC Vertical Turning Lathe

This system applies to machine tools such as carbide and ceramic cutting tools, for ferrous metals, nonferrous metals and internal an external cylindrical surface ,face ,cutting slots, screw and rotary surface of non-metallic parts for coarse, semi-refined and refined processing.

There are three specifications available such as high-speed type, standard type, and heavy-load type.

High-speed cutting: the max cutting speed is up to 2000m/min.The fast moving speed of the tool holder (horizontal and vertical)is up to 12m/mn..

The main transmission is driven by AC main shaft servo motor. Two-step variable speed uses the imported ZF gearbox. High-speed rotary workpieces are carried out with static and dynamic balance .High-precision transmission gears and gear grinding process are used to realize high transmission efficiency, low noise and reliable and stable operation under high speed.

The feed system is driven by AC servo motor an d the motor carries out direct linkage with ball screw by soft coupling to realize non-transmission clearance with high-precision operation.

The column is in type of thermal symmetry and it is installed in the base of working platform. By the calculation of finite elements of the computer, effective vibration isolation measures are adopted with the features of high stiffness and high anti –vibration capacity.

The working platform is in type of thermal symmetry and the main shaft adopts double short and circular column roller bearing center with high-precision and adjustable radial clearance while the axial direction utilizes large thrust sphere bearing with high-precision as the rolling guide and then the cooling device of oil temperature is equipped with, thus, the working platform is featured with high rotation precision, large bearing capacity and small thermal deformation.

The feed motion of tool holder and ram adopt straight line bidirectional roller rolling guide to make the motion of tool holder own stable motion, high transmission efficiency and excellent precision retentively.

CNC system adopts Siemens or FANUC system or other systems appointed by the user.

The machine tool is equipped with chip removal device and semi-closed hood.

Upon the demands of the users, tool magazine, butted-knife installation within the machine, boring-milling function, function of indexing and feed of working platform, grinding function, left vertical tool holder as well as full-closed-loop control etc .can be offered.

Therefore, the electric components, hydraulic components and the functional parts all select world famous brand.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

CK5235E CNC Double Column Vertical Lathe China

CNC Double Column Vertical Lathe

CNC Double Column Vertical Lathe adopt the most advanced production technology, modularization design and analysis of infinite elements are adopted to integrate machine, electricity and hydraulics the advanced technology, which represents high-precision exquisite cutting.

Siemens 802DSL or Siemens 802C CNC system which owns 100% full manual switch and operation function, that means no programming is needed even for the common operator. Manual operation is convenient and practical. Two-step machinery variable speed and ultra-large torque DC motor stepless speed control to realize turning with constant line rate.

Premiumcasting (HT300) is handled by heat aging. The guide on the beam is embedded with chromium-masurium-manganese guide plate.

The left too holder adopts the common type while the right one utilizes CNC system; both of the two tool holders can all be selected as CNC mode. The guide of working platform adopts constant current oil supply with constant current motor with the feature of stable precision; The hydraulic oil utilizes refrigerator for constant-temperature cooling and reducing the variant quantity of the working platform.

Different lubrication parts adopt automatic lubrication pump for automatic timing and quantitative oil supply. High precision ball screw adopts imported bearing (Germany INA) for supporting.

JB/T9934.1-1999 precision inspection of CNC vertical lathe is performed. JB/T9934.2-1999 technical specification of CNC vertical lathe.

Best after-sale service (pre-sale, sale, after-sale, installation, debugging, training and guarantee)

Machine tool adopt lots of imported parts (electrical, servo motor, servo drive, hydraulic parts, bearings, screw, planetary reducer, etc.), reliable quality assurance .

Gear box adopts high accuracy grinding gears. With beams stainless steel protective and walking board etc.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

CK5235E CNC Double Column Vertical Lathe China

CNC Double Column Vertical Lathe

CNC Double Column Vertical Lathe adopt the most advanced production technology, modularization design and analysis of infinite elements are adopted to integrate machine, electricity and hydraulics the advanced technology, which represents high-precision exquisite cutting.

Siemens 802DSL or Siemens 802C CNC system which owns 100% full manual switch and operation function, that means no programming is needed even for the common operator. Manual operation is convenient and practical. Two-step machinery variable speed and ultra-large torque DC motor stepless speed control to realize turning with constant line rate.

Premiumcasting (HT300) is handled by heat aging. The guide on the beam is embedded with chromium-masurium-manganese guide plate.

The left too holder adopts the common type while the right one utilizes CNC system; both of the two tool holders can all be selected as CNC mode. The guide of working platform adopts constant current oil supply with constant current motor with the feature of stable precision; The hydraulic oil utilizes refrigerator for constant-temperature cooling and reducing the variant quantity of the working platform.

Different lubrication parts adopt automatic lubrication pump for automatic timing and quantitative oil supply. High precision ball screw adopts imported bearing (Germany INA) for supporting.

JB/T9934.1-1999 precision inspection of CNC vertical lathe is performed. JB/T9934.2-1999 technical specification of CNC vertical lathe.

Best after-sale service (pre-sale, sale, after-sale, installation, debugging, training and guarantee)

Machine tool adopt lots of imported parts (electrical, servo motor, servo drive, hydraulic parts, bearings, screw, planetary reducer, etc.), reliable quality assurance .

Gear box adopts high accuracy grinding gears. With beams stainless steel protective and walking board etc.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

DVTCK5250 CNC Double Column CNC Lathe

CNC Double Column Vertical Lathe

1. The most advanced production technology of vertical lathe, modularization design and analysis of infinite elements are adopted to integrate machine, electricity and hydraulics the advanced technology, which represents high-precision exquisite cutting. 2. Siemens 802DSL or Siemens 802C CNC system which owns 100% full manual switch and operation function, that means no programming is needed even for the common operator. Manual operation is convenient and practical. 3. Two-step machinery variable speed+ ultra-large torque DC motor stepless speed control to realize turning with constant line rate. 4. Excellent casting (HT300) is handled by heat aging. 5. The guide on the beam is embedded with chromium-masurium-manganese guide plate. 6. The left tool holder adopts the common type while the right one utilizes CNC system; both of the two tool holders can all be selected as CNC mode. 7. The guide of working platform adopts constant current oil supply with constant current motor with the feature of stable precision; the hydraulic oil utilizes refrigerator for constant-temperature cooling and reducing the variant quantity of the working platform. 8. Different lubrication parts adopt automatic lubrication pump for automatic timing and quantitative oil supply. 9. High-precision ball screw adopts imported bearing (Germany INA) for supporting. 10. JB/T9934.1-1999 precision inspection of CNC vertical lathe is performed JB/T9934.2-1999 technical specification of CNC vertical lathe 11. Lots of imported parts (electrical, servo motor, servo drive, hydraulic parts, bearings, screw, planetary reducer, etc.), reliable quality assurance. 12. Gear box adopts high-accuracy grinding gears. 13. With beams stainless steel protective and walking board etc.

|