Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

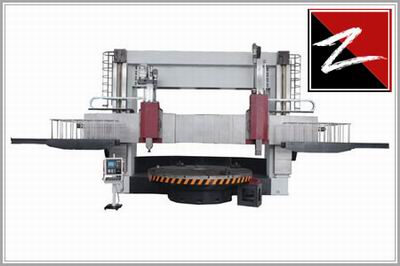

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

CXK5231 CNC vertical turning center

CNC Vertical Turning and Milling Center

The CXK series CNC Vertical Turning and Milling Center was developed by our company, it is a new type turning and milling center with new functions, high precision and high efficiency. The machine is widely used in aerospace, shipbuilding, nuclear power, high speed railway, etc

CXK series CNC vertical turning and milling center have the functions same as general CNC vertical. All process except undersurface can be finished with one time clamping, such as turning, milling, boring, tapping, etc. Many kinds of more complicated curved surfaces, such as vane, can be also conducted with, if double swing milling head is set up. It has x and z axis, c three CNC for triaxial linkage.

The main components and main transmission adopts thermal symmetrical structure, with high thermal stability.

Worktable main shaft adopts high-precision double row cylindrical roller

bearing for centering in radial direction, and adopts large ball thrust bearing for loading in axial direction. Worktable is provided with the functions of precision indexing and turning and milling feedings.

The beam has hierarchical positioning function.

The ram adopts high-precision ball screw transmission. Machine is setup

with ATC with12-20 tool station.

Siemens 840DSL system (user can appoint other system) is adopted;

servo motor and servo driver all utilize Siemens products.

All the castings are made of HT300 gray cast iron (ram is made of ductileiron) which is treated with artificial heat aging, high-quality processing and improved assembly process. All the electrical parts, bearings, key parts, hydraulic parts were picked from the manufacturers with world famous brand.

Complete fitting configuration allows the user to put into operation only by preparing cutting tool and measuring tool. Perfect after-sale service, two years guarantee.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

CXK5263 CNC Vertical turning center china

CNC Vertical Turning and Milling Center

The CXK series CNC Vertical Turning and Milling Center was developed by our company, it is a new type turning and milling center with new functions, high precision and high efficiency. The machine is widely used in aerospace, shipbuilding, nuclear power, high speed railway, etc

CXK series CNC vertical turning and milling center have the functions same as general CNC vertical. All process except undersurface can be finished with one time clamping, such as turning, milling, boring, tapping, etc. Many kinds of more complicated curved surfaces, such as vane, can be also conducted with, if double swing milling head is set up. It has x and z axis, c three CNC for triaxial linkage.

The main components and main transmission adopts thermal symmetrical structure, with high thermal stability.

Worktable main shaft adopts high-precision double row cylindrical roller

bearing for centering in radial direction, and adopts large ball thrust bearing for loading in axial direction. Worktable is provided with the functions of precision indexing and turning and milling feedings.

The beam has hierarchical positioning function.

The ram adopts high-precision ball screw transmission. Machine is setup

with ATC with12-20 tool station.

Siemens 840DSL system (user can appoint other system) is adopted;

servo motor and servo driver all utilize Siemens products.

All the castings are made of HT300 gray cast iron (ram is made of ductileiron) which is treated with artificial heat aging, high-quality processing and improved assembly process. All the electrical parts, bearings, key parts, hydraulic parts were picked from the manufacturers with world famous brand.

Complete fitting configuration allows the user to put into operation only by preparing cutting tool and measuring tool. Perfect after-sale service, two years guarantee.

|

|

|

vipeak

|

Conveying Systems

|

|

|

|

|

One of the most popular stone-crushing equipments in the world, Jaw Crusher is ideally suitable for primary and secondary crushing. The highes tanti-pressure strength of crushed material is 320Mpa.

Our design and production features the absolute advantages in this field. With large crushing ratio, even granularity, simple structure, reliable operation, convenient maintenance, low cost. It is widely used in mining, metallurgy, construction, highway, railroad, and chemistry industries and etc.

The Crushing form of this series Jaw Crusher is driven-squeezing style. Its working principle is: Motor drives belt and belt pulley, makes moving jaw up and down through eccentric shaft. When the moving jaw is up, the angle between lining plate and moving jaw becomes large, and this will push moving jaw plate close to the fixed jaw plate. During this process, the material is crushed and ground, thus the crushing will be done. When the moving jaw is down, the angle between lining plate and moving jaw becomes small, the moving jaw plate will leave the fixed jaw plate on account of the effect of pulling bar and spring, and then the crushed material will be discharged from the lower opening of the crushing room. With the motor continuously rotating and the material periodically crushed and discharged by the crusher, the mass production can be realized. company: ZhengZhou Vipeak Heavy Industry Machinery

Tel:86-371-67770550

Fax:86-371-67431834

Source from: http://www.vipeakgroup.com/

|

|

|

Henan Kefan miming machinery Co.,Ltd.

|

Conveying Systems

|

|

|

|

|

The Magnetic Separator can separate raw materials with different magnetic rigidities. The Magnetic Separator machine in stone crusher series works under the magnetic force and machine force. Magnetic Separators are designed to separate ferromagnetic materials. The Magnetic Separators in stone crusher series are available in designs and to provide solutions for all applications. The heart of each separatoris the magnetic system with its unique design, which has proven to be efficiency.

The Magnetic Separators in stone crusher series are available in cyclic design with vessel whose diameters are smaller than 3mm.Magnetic Separator is a kind of efficient equipment for processing fine, feebly magnetic minerals, such as hematite, limonite, wolfram, limonite, and tantalum-niobium, etc. In recent years, Magnetic Separator in stone crusher series is also more and more applied in purifying quartz, feldspar and nephrite. Magnetic system is a ring-shape chain closed magnetic circuit with energizing coils made of copper tube and cooled internally by water. Grooved plates made of magnetic conductive stainless steel are used as magnetic matrix.

Henan Kefan Mining Machinery Co.,Ltd. is a professional mining machinery manufacturer.Our Company provide jaw crusher, brick making machine ,mining machinery,Briquetting Machine,

cone crusher,vibrating screen,conveyor,Stone Crusher,hammer crusher,roller crusher,circular vibrating screen,grinding mill,Ball Mill,cement equipment,belt conveyer,vibrating feeder,rotary dryer,Crusher,cutting machine,dry machine,cone crusher,magnetic separator,casting machine, etc.

|

|

|

Henan Kefan miming machinery Co.,Ltd.

|

Conveying Systems

|

|

|

|

|

Raymond Mill(Raymond Grinder) in stone crusher series is relevant towards the grinding and processing of more than 280 types of non-flammable and non-explosive materials with hardness lower than 7 and humidity lower than 6% in mining, construction ,chemical industry and metallurgy, such as barite, calcite, feldspar,talcum, marble, limestone, clay, glass. The fineness from the finished product after Raymond Mill in stone crusher series could be adjusted from 100 mesh to 325 mesh according to specific requirements of clients.

Raymond Mill in stone crusher series: Load the stuff for grinding evenly and continuously into the grinding chamber of the main frame. Due to the centrifugal force in rotation, the roller swings outward and presses closely upon the ring. The shovel carries the stuff to the space between the Raymond Mill roller and ring. When the Raymond Mill roller rolls, the stuff is thus grinded.After being grinded, the stuff is to be routed to the sorter along the wind belt of the blower and the rough powder will be put back to the stone crusher for regrinding. The fine powder flows into the product cyclone collector together with airflow and is expelled from the powder output pipe as product.In the grinding chamber, since the stuff may contain moisture to some extent, the heat generated during grinding makes the moisture evaporated; since the pipeline joints are not airtight, the external air is sucked in and the circulation air mass increases. In order to enable the grinder to work under negative pressures, the increased airflow is guided to the deduster anew sequentially to the atmosphere after purification.

Henan Kefan Mining Machinery Co.,Ltd. is a professional mining machinery manufacturer.Our Company provide jaw crusher, brick making machine ,mining machinery,Briquetting Machine,

cone crusher,vibrating screen,conveyor,Stone Crusher,hammer crusher,roller crusher,circular vibrating screen,grinding mill,Ball Mill,cement equipment,belt conveyer,vibrating feeder,rotary dryer,Crusher,cutting machine,dry machine,cone crusher,magnetic separator,casting machine, etc.

|