Tatiana Ponce – Brand Director of Polylana®

Our recent interaction with Tatiana Ponce, Brand Director of Polylana® - talks about their low-impact fiber that has the same characteristics as acrylic and wool fiber- Polylana®, and how it can be used as an eco-efficient solution for knitwear and other applications in the textile market.Polylana® fiber, a low-impact replacement for acrylic fiber

2022-06-02 10:37:45 – NetherlandsDutch start-up, The Movement, has developed an innovative low impact replacement to acrylic and wool fiber- Polylana® fiber.

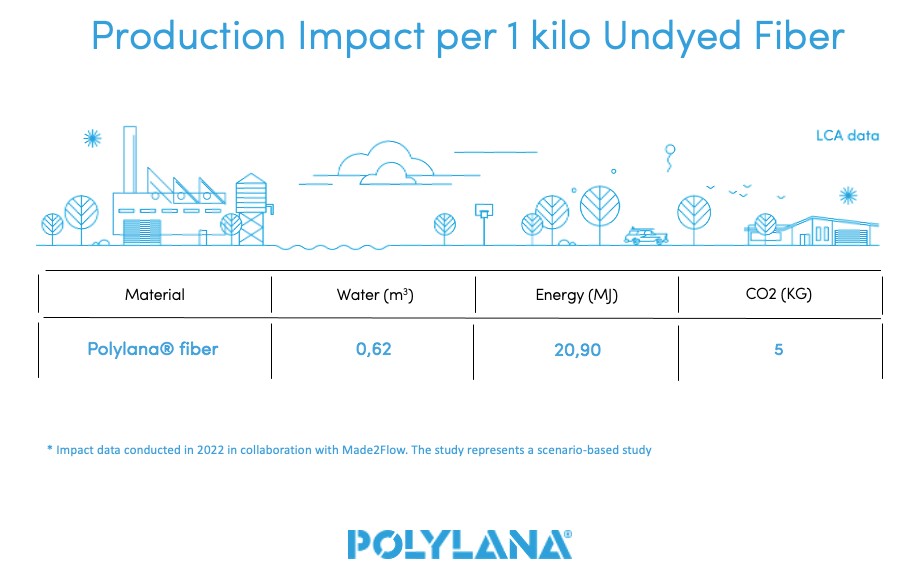

It has the same 'wool-like' hand feel and characteristics as acrylic fiber, but with a far reduced environmental effect because it utilizes less energy, water, and emitting less CO2 during manufacture. Polylana® fiber is made up of 50% recycled material and 50% modified polymer and can be spun and dyed in the same way as acrylic can.

Our recent interaction with Tatiana Ponce, Brand Director of Polylana® - talks about their low-impact fiber that has the same characteristics as acrylic and wool fiber- Polylana®, and how it can be used as an eco-efficient solution for knitwear and other applications in the textile market.

YnFx: What inspired the creation of Polylana® fiber?

Ponce: Polylana® fiber was born out of a need to find a low-impact alternative to acrylic. Some years ago, Feico van der Veen, the founder of The Movement was looking for better material. He realized that the enormous impact of acrylic is extremely harmful to the environment. There was no material in the market that could fulfill this need, so he decided to develop his own low-impact fiber and gave it the name Polylana® fiber. Polylana® fiber is an innovative staple fiber with the same characteristics as acrylic; it’s bulky, soft, and has a great hand-feel. Compared to acrylic we are saving water, energy and reducing CO2 emissions and environmental impact. Not just different, but better.

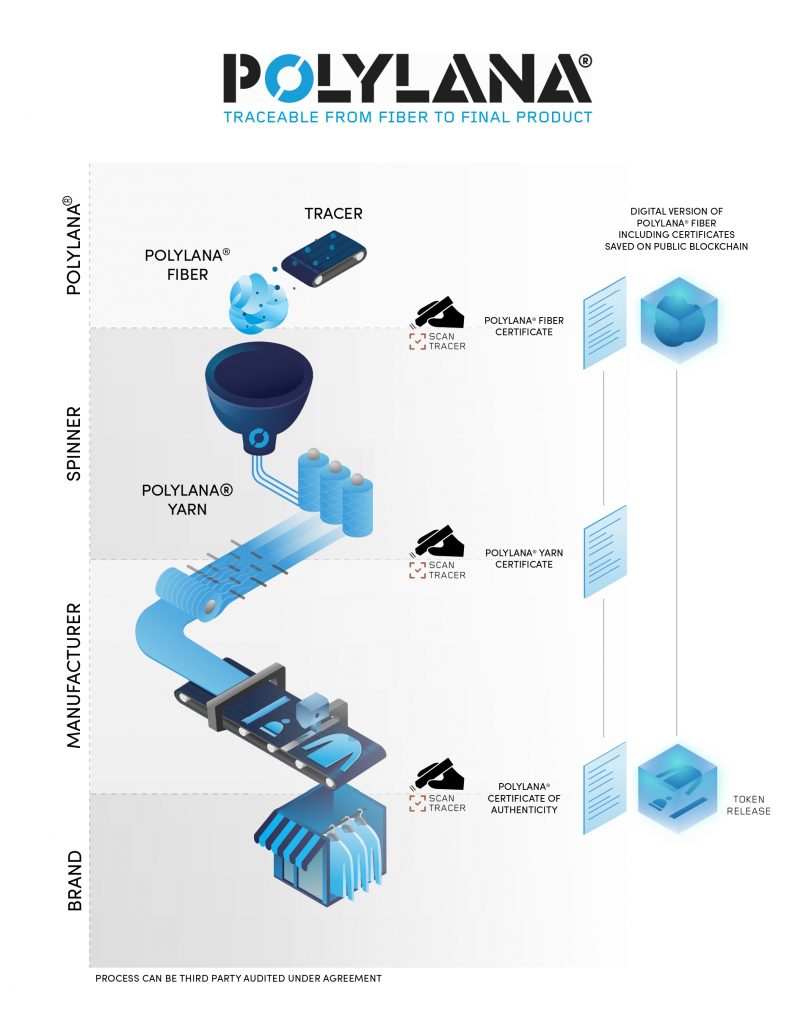

YnFx: How do you ensure traceability in Polylana® fibers?

Ponce: Polylana® fiber is traceable from fiber to the final product. The fiber contains a physical tracer that is added during the production process. The tracer can be scanned with a USB hand scanner during every stage of the supply chain, which guarantees the genuine fiber in the final product. For the administration and certification, we use blockchain. In this secured system, we make sure all the information is stored and shared with the right partners. See the infographic for a visualization of our procedure.

YnFx: What makes Polylana® fiber distinctive from the other alternatives available in the market?

Ponce: Polylana® is an innovative staple fiber with the unique and excellent characteristics of acrylic and wool but at a much lower impact. This is what makes Polylana® fiber distinctive from other fibers. Polylana® fiber is bulky, soft and has a ‘wooly’ look in the final product. Polylana® fiber dyes in the same way as acrylic and is 100% recyclable.

YnFx: What is the environmental footprint of Polylana® fiber?

The potential reduction of CO2 emissions is around 80% when compared to the production of acrylic fiber in the same conditions and geographic areas. Also, with Polylana® fiber, the potential savings of water are around 85% compared to acrylic.

YnFx: What sustainable measures has the company taken in its production process?

Ponce: Parts of our raw materials come from post-consumer plastic bottles (rPET). Besides that, we are working with a network of spinning partners that are spinning yarn with Polylana® fiber. We require our spinners to have certain standards and certifications in order to be our partners. In this way, we look further than only into our own product. Collaborating and creating synergy is key in order to achieve sustainability goals worldwide.

YnFx: What are the possible applications of Polylana® Fiber?

Ponce: Polylana® fiber has four applications:

1) Knitwear

2) Woven fabric

3) Faux fur

4) Filler (insulation)

In the beginning, Polylana® fiber had a strong association with accessories, as the fiber first was available in the market in beanies. Right now the largest sales market is knitwear, around 80% of Polylana® fiber is used for knitwear. Besides knitwear, Polylana® fiber can be applied in woven fabrics and faux fur. We are currently doing developments for a fourth application, loose fill. This is not yet available on the market.

YnFx: What are the future plans of the company?

Ponce: As sustainability is increasingly becoming a standard in the fashion industry today, our vision is to offer brands a low-impact fiber with great performance. By making Polylana® fiber available to the market, brands will reduce impact and achieve sustainability goals, without compromising on quality and performance of the final product. Our company’s future plans are to further reduce the impact of the fashion industry on the production side, by creating even less impact with the composition of Polylana® fiber, and to prove claims with our traceability system.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide