Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Dalian Zhenghe International Trade Co. Ltd

|

Marking Machine

|

|

|

|

|

CK5116 CNC single column vertical lathe

CNC Vertical Lathe Numerical control system is Siemens or Fanuc CNC.

Bring in finite element analysis,specially designed aiming at high efficiency,high rigidity,heavy cutting etc working conditions.

1 The pillar and base plate both use big-size box arrangement,offering the biggest Z shaft ram section with 230*200 size,can support over heavy cutting.

2 The symmetrical layout can reasonably avoiding heat deformation,reasonable arrangement and many times of temper and aging processings,has guaranteed a long time stability for the lathe's accuracy.

3 The radial direction of main shaft use P4 level double column roller bearing,the axial direction use P4 level big size thrust bearing,at the same time of ensuring high rotating accuracy,the high load capacity has also been ensured.

4 The hydraulic system use machine-outside cycling,which can take away the heat efficiently.The oil pump is always in a unloading state to avoid the lathes' temperature rise.When the lathe is equipped with second main shaft,the lathe is equipped with oil cooler.

5 Big diameter ball screw,X shaft ball screw pre-stretching,which has ensured a high position accuracy and can compensate heat deformation.

6 The lathe has big openings,which is convenient for components handling,loading and unloading.the operate button face can have a

90°turning,good agreeableness.

7 There have kinds of configurations for users to choose from,like standard type,heavy load type and high speed type.Also we can choose ZF two-section transmission case or our company's four-section transmission case on the basis of users requirement.

|

|

|

Dalian Zhenghe International Trade Co. Ltd

|

Marking Machine

|

|

|

|

|

C5250 double-column vertical lathes in china

1 This series of double column vertical lathe is suitable for rough,refine machining for motors,hydraulic turbine, aviation,mining machinery,and metallurgy those like of mechanical industry,and can be used for rough,refine processing to inside and outside cylindrical faces,inside and outside circular conical faces,end face and grooving.

2 The lathe's main transmit include alternating current and direct current two kinds,and the worktable has sliding guide rail and static pressure guide rail for users to choose from.

3 The logic control for lathes' main transmit use Japan OMRON edited program controlled PC controlled,good reliability.

4 The vertical lathes feeding system is alternating current 18 grades.

5 We can provide side knife set,cooling unit,digital display etc accessories according to users requirement.

6 All the electricity parts use Schneider or Simens,worktable's flow control use Germany XiDeFu flow signaling device;the lubrication for the left and right knife set choose domestic famous lubrication station.

7 This series of vertical lathe all adopt high quality resin sand castings,

after temper and aging,the lathes' rigidity and accuracy durability is good.

|

|

|

Dalian Zhenghe International Trade Co. Ltd

|

Marking Machine

|

|

|

|

|

C5112 single column vertical lathe machine

1 This series of vertical lathe is suitable for mechanical processing

in many industries,can be used for machining processing such as rough and finishing machining to inside and outside cylindrical faces,inside and outside circular conical faces,grooving and notch cutting.

2 The worktable of the vertical lathe uses both dynamic and static pressure guide rail,the radial direction of the main shaft use NN30 double column cylindrical roller bearing,so the worktable has big load,high rotation accuracy.

3 The slide part all adopt pasted-imported TSF slideway soft belt with low friction coefficient,and feeding no creeping.

4 The vertical lathe's rail head is equipped with pentagon knife set(can choose square ram),the side knife set equipped with square knife table,both the two knife sets use hydraulically balance.

5 Both the horizontal and vertical movement for the rail head use sliding screw transmit.

6 We can optional equip digital display etc accessories according to

users requirement,and logical control for the main transmission can choose program PC controlled.

7 All the electricity parts of lathes use Schneider or Simens,good reliability.

8 This kind of vertical lathe has good appearance,agreeableness and convenient for operate and repair.

|

|

|

XingBang Heavy Industry Machinery Co., LTD

|

Marking Machine

|

|

|

|

|

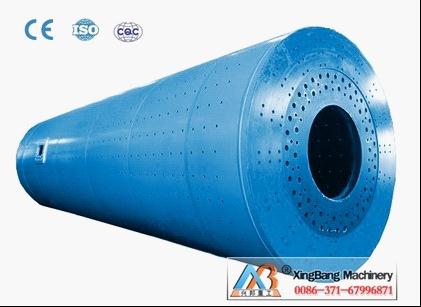

Cement Ball Mill-cnxb0613

Characteristics of Cement Ball Mill:

An equipment for cement factories ;

To grind cement clinkers and other materials;

Applied in construction, metallurgy, electricity and chemistry;

Type:Ordinary and High yielding type&;

The machine runs smoothly and works realiably.

Working Process of Cement Ball Mill;

Through material hollow shaft spiral the material is sent to the first mill chamber, in which there are ladder liner or corrugated linings, with steel balls of different specifications in it. When cylinder rotating, centrifugal force will produce steel ball fall down from a certain height, thus impacting and grinding the materials. After coarse grinding in the first chamber, materials enter into the second chamber through a single diaphragm. In this warehouse with flat lining board and steel balls in it, materials are further grinded.

Working Principle of Cement Ball Mill;.

Cement ball mill is a new energy-saving grinding equipment designed by domestic processing machinery experts after absorbing the newest grinding technology home and abroad. It not only improves the productivity and crushing ration, but also expand the application range. It performs an excellent job in secondary crushing, finely crushing and super finely crushing, from limestone to basalt, from stone production to various ores crushing. It is now a new-generation product in mining construction that can replace spring cone crusher and update general hydraulic cone crusher and an ideal equipment for large-scale stone and mining crushing, having the features of low investment, energy saving, simple structure, easy operation, safety use, realibility, etc and applicable to grinding and mixing general and special materials. Customers can choose suitable model, lining board and medium type according to material proportion, hardness, output as well as other factors.

http://www.china-xingbang.com/11.html

Ball Mill

Rotary Kiln

Jaw Crusher

Stone Crusher

Contact person: Luz Liu

Tel: 0086-371-67996871 0086-371-67996872

E-mail: [email protected]

MSN: [email protected]

WEB: http://www.china-xingbang.com/

|

|

|

Zhe Gong CNC Welding Machine(ZGTEK) Co., Ltd

|

Marking Machine

|

|

|

|

|

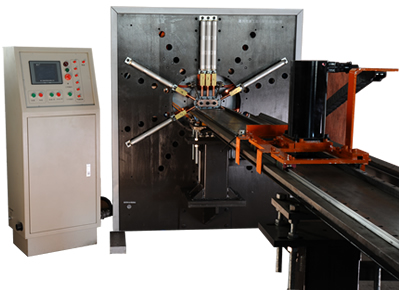

Oval cage making machine

Gear rack rail, server motor, high accuracy

Ring space precision:0.1mm

Oval cage making machine

Control unit: KD-DL08D

Weld galvanized(GI) wire direcly without damaging zinc plating

Ring space is programmable and bag cage is pulled by mechanism formed by gear rack and step motor, no accumulated locating tolerance, ring space precision is 0.1mm, pulling speed is 0.4m/s, especially applicable to the bag cage with different ring spaces

Specification

Input voltage: 380V(2 phase) or specified by customer

Power frequency: 50/60Hz

Cooling method: natural cooling

Air pressure: 0.6-0.8 MPa

Insulation grade: F

Power capacity: 80 KVA

Instant power in sync mode: 36 KVA

Instant power in async(time-sharing) mode: 18 KVA

Air flow: 300 L/min

Weight: about 1300KG

Features

Rails (up to 9000mm) and carriage equipped and connected to the welding unit. The front end of the rail is adjustment-free. Good linearity can be achieved for wire cages

Equipped with auto feeding unit, no restrictions on ring space

Four air tanks, short air route inside the machine ensures quick response of the cylinder

25mm front plate resulted from one-time machining, firmly secure that the welding cylinders are on the same plane and perpendicular to the axes, thus the linearity of the cage can be ensured

Stroke-adjustable cylinders increase welding speed, pre-pressing only takes 0.08s

Controlled by micro-computing unit

Time-sharing power-on transformer reduces the burden on local electricity grid

|