Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

Weiber modular Clean Room Tent is the most economical approach and design for cleanroom needs. This design is commonly used in the microelectronics and medical mold injection industry as well as many others. A major advantage provided by Weiber Clean Room Tent is its ability to be enlarged or reduced according to customers’ requirement. Clean room tents can be designed to provided class 100 or class 10,000 level of cleanliness as per U.S. Fed Std. 209. The Clean Room Tent is a designed and constructed room in which the air supply, air distribution, filtration of air supply, materials of construction, and operating procedures, are regulated to control airborne particle concentrations to meet appropriate cleanliness levels. Weiber also provides protocols for the user for entering into the clean room.

Tent addresses the need to remove particles from the air, it also has options that eliminates or reduces the chance of contamination from being introduced into the room. Weiber is made using good quality raw material and is made available to the client at reasonable market price. These scientific instruments ensure clean and fresh air under the tent area by neutralizing the negative ions. Weiber is counted amongst the leading manufacturers/developers/supplier/exporters/ engineer/service providers of Clean room tents. The ceiling and wall panels are constructed of stainless steel.

Salient Features

Stainless steel bench

Modular and Prefabricated

Single pass or recirculating

HEPA filter offers filtration efficiency of 99.97%.

Expandable and upgradable

FD A approved & ISO certified

Portable & Economical

T-Bar ceiling complete with integrated lighting and filtration High quality performance

Rigid wall, withstand

Technical Specification

Clean Room construction

Stainless Steel/Mild Steel

Interior height

8 - 14 feet Height

Adjustable pressure

0.06W.C.

Outer Room Size

L-4 XW- 7 X H-14 ft.

Filter

Filter

Types

Class 100,000 to Class 10

Wiring

Reloc Wiring System

Current Required

20 amp

PVC Curtain

200 x 3 mm

|

|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

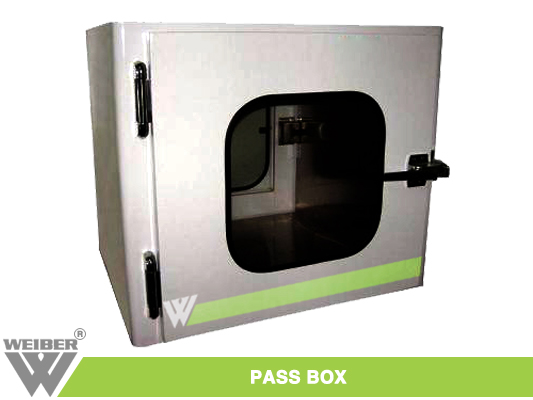

Weiber pass box static is designed to minimize traffic and contamination entry into the clean room. Our Pass box comes under the international standard and is used for transferring the material form one clean room to other clean room without air of clean room also. Weiber specializes in both standard and customized Pass Box.

Weiber custom made static pass box is an inexpensive way to maintain the cleanliness of your clean room. These boxes operate on the principle of one door opening at a time with electromagnetic interlocking so as to avoid any possibility of cross contamination. With stainless steel coating and rigid base these tailor made equipment provide optimum performance. They are available in Stainless Steel Construction with interlocking arrangement, with and without built in HEPA air barrier. Weiber offers low cost and easy installation of its product.

Construction details-The unit is made of Commercial board & all its external & internal surfaces are duly laminated. Each hinged door in our pass box has wide glass viewing window, through which material kept in the pass box can be seen. These doors are electrically interlocked type, so that any one door can be opened at a time. UV & fluorescent light and HEPA filter can be provided optionally.

Salient Features

Abrasion-resistant epoxy-coated steel

Easy to clan stainless steel base

Wall grouted modules

Floor and wall mounted design

Maximum chemical resistance construction

Easy installation & Economical

Swing type doors

Applications

Space applications

Life science

Chemical industry

Bio medical

Diagnostics labs

Pharmaceutical industry

Technical specifications

Construction

Stainless Steel 304 / 316 / 316L or PCRC Powder Coated

Door

Mechanical or Electromagnetic Interlocking

Accessories

Hour Meter, Fluorescent light, UV light, Buzzer and Indicator lamps

Filtration efficiency

≥ 99.99% @ ≥ 0.3μm

Power Supply

220 / 230 Volts

|

|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

Weiber pass box dynamic are self-contained units installed at the entrance to clean rooms. They minimize the amount of particulate contamination and is easy to install and adaptable to existing facilities. The pass boxes offered by us are the safest equipment which contain clean zone cross contamination of material in transit. These boxes operate on the principle of one door opening at a time with electromagnetic interlocking so as to avoid any possibility of cross contamination. Weiber is counted amidst the leading manufacturers/distributors/suppliers/developers/exporters/engineers/ service providers of Pass Box Dynamic.

Our custom made units are easily installed on the wall between clean room and other room and are made with good Abrasion-resistant epoxy-coated steel. With UV Light these are fitted with a mechanical interlock system that prevents both doors from being opened at the same time. Weiber offers unmatched prices, usage and application for various pharmaceutical industries.

Construction Details- Our tailor made unit has double walled construction and is available in powder coated Mild Steel, SS 304 / SS 316/ SS 316L or a combination of both.

Salient Features

Finish - Matt finish

Confirms to GMP norms

Mechanical or Electromagnetic Interlocking

Floor and wall mounted design

Maximum chemical resistance construction

Modular & economical

Applications

Medical implant

Medical devices

Educational institution

Vaccine manufacturers

Food processing industry

Technical Specifications

Construction

Stainless Steel 304 / 316 / 316L or PCRC Powder Coated

Door

Mechanical or Electromagnetic Interlocking

Accessories

Hour Meter, Fluorescent light, UV light, Buzzer and Indicator lamps

Filteration efficiency

≥ 99.99% @ ≥ 0.3μm

HEPA filter

In-Built

U.V lamp

In-Built

Power Supply

220 / 230 Volts

|

|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

Garment storage cabinet provides a clean storage area for clean room garments and is available in several configurations and sizes. The Laminar flow garment storage cabinets are reliable and durable, and have low operating noise levels. Clean room garments cubicles can accumulate contamination and garment cabinets, which in some or the other way makes an optimistic contribution to maintain the sanitation of the clean room environment. ULPA filtered airflow helps to keep clean room garments clean and tidy, when being handled and stored. Each and every material storage cabinet in the garment storage cabinet is stored visibly and systematically. Weiber manufactures both standard & customized Clean Room Garment Storage Cabinets for pharmaceutical industries.

Weiber HEPA filtered garment storage cabinets offers unmatched prices, specifications and usages for various scientific research laboratories.

Features

Energy efficient

Disposable prefilter

Reliable rocker switches

Versatile

Easy installation & low price

Built in solid state variable speed controllers

|

|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

Weiber dispensing booth eliminates powder contamination in order to protect the operator and the surrounding environment and are used for mixing, weighing and dispensing of powder. Moreover our down flow dispensing booths operate on the re-circulation of air principle. The Clean air exiting the HEPA filters are supplied from the top which suppresses any dust cloud generated during the process of material handling. Weiber manufactures and supplies Pharma dispensing booth in India used for filling, refilling, weighing and sampling of raw materials and compounds.

Our Clean Room dispensing booths are high in quality and performance and are available in much competitive rates. The air forced downwards is extracted at low level into the booth's filtration system where dust particles are contained at each level of filtration prior to being re-circulated back into the booths' air stream.

Weiber Ultra Clean HEPA dispensing Booth & Pre filter unit offers unmatched prices, specifications and usage for pharmaceutical industries.

Construction Details- The Clean room sampling booth is available in different options of side walls i.e.: the side walls available are of stainless steel or polycarbonate curtains based on the application.

Salient Features

Negative pressure inside the booth prevents the escape of fine powder from the work area

Fully integrated system

Easy installation & economical

Stainless steel AISI 304 structure

Dynamic gasket to guarantee the perfect sealing of the filters

Down cross is equipped with N°3 fans with AC frequency control

Applications

Product Dispensing

Large scale dispensing & weighing

Pharma industry

Dispensing of raw materials

Chemical industry

Technical Specifications

Filters

Aluminum framed HEPA filters with a minimum efficiency of 99.99% at 0.3 micron.

Air flow

90 FPM (0.45 m/s) , 10 FPM (0.05 m/s)

Noise level

65 +- 5 DB

Motor / Blower assembly

Direct drive continuous duty ¼ HP with sealed bearings.

Pre filter

Washable type pleated pre filter with 90% efficiency.

Particle Containment

Particle Containment (OEL < 100 µg/m3)

Finish

Stainless steel, satin non glare or painted

|