Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

Clean Room Equipments

Air Environment Monitoring Equipments

Air Showers

Biosafety Cabinets

Clean Room Accessories

Chemical Hood

Glove Box

Laminar Air Flow

Modular Clean Room

Pass Box

Pharmaceutical Application Equipments

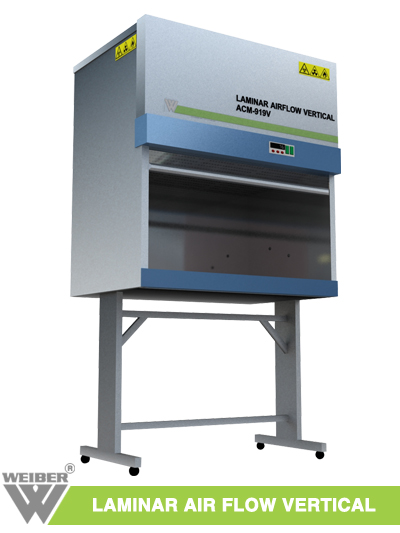

Home > Laminar Air Flow > Vertical Laminar Air Flow

Vertical Laminar Air Flow (ACM-916V)

|

|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

Weiber offers a wide range of high quality Soft Wall Clean Room systems to suit customer’s requirements. Weiber has designed Clean Room for industrial and scientific research to provide a low level of environmental pollutants. This scientific equipment offer entire manufacturing facilities and is widely used in semiconductor manufacturing, biotechnology, the life sciences and other fields that are very sensitive to environmental contamination. It offers a cost-effective solution to create a clean area within an existing room or space. Weiber is counted amidst the leading manufacturers/developers/ exporters/distributors/ exporters/engineers and service providers of Class 100 soft wall clean room.

The Clean Air for the system is created by the room air cleaning device(s) that are fixed to the outside walls or the ceiling of the room. As the air enters the room all air is drawn through a HEPA filter (99.997% efficient at 0.3 microns) which creates a positive pressure in the room and therefore provides a clean area. The ceiling and wall panel are constructed of stainless steel.

These customized clean room spans area of 6 to 34 feet and interior room height ranges from 8 to 14 feet in height. It internal pressure is adjusted through variable wall dampers. It offers low cost with interchangeable framework. Clean Room air conditioning system controls humidity upto 40%. Its modular design makes installation easy and fast. Modular Softwall Cleanrooms are designed to provide clean environments from Class 100,000 to Class 10 (ISO Standards Class 3 to Class 8).

Salient Features

Light Weight

Portable & Economical

FDA approved

Modular and Prefabricated

High quality performance

Interior height of 8 to 16 ft.

Clean Room spans upto 34 feet.

Single pass or recirculating

Expandable and upgradable

Rigid wall, withstand high internal pressure.

Adjustable pressure upto 0.06 W.C.

T-Bar ceiling complete with integrated lighting and filtration

Technical Specifications

Clean Rom construction

Stainless Steel

Interior height

8 ~ 14 feet Height

Adjustable pressure

0.06W.C.

Modular width

6 ~34 feet

Rom Size (L X B X H)

4 X 7 X 14 feet

Sliding Door width

36, 48 and 60 inch

Entrance Door Size

45 X 93 inch

Filter

HEPA Filter 99.97% efficient

Types

Class 100,000 to Class 10

Wiring

Reloc Wiring System

Current Required

20 amp

|

|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

Weiber Hard Wall Clean Room provides the rigidity and durability of a freestanding room. All components are factory-assembled and tested before shipping, and on-site installation is usually completed in less than a day. Weiber air shower design offers unmatched design, prices, specifications and usages for researchers and scientists. All equipments are build under strict observation of technicians & experts. Clean Room equipments involve four basic principle of cleanliness involving: not to bring any dust, not to generate any dust, not to accumulate any dust and removes dust quickly.

Vertical finishing strips, fabricated of mirror-finished 304 stainless steel, hold hardwall panels securely in place. They are available in three rigid materials: Acrylic panels, Static-Dissipative PVC Panels and Polycarbonate. It features Gel-Sealed HEPA Filtration System, Fluorescent lighting with plastic egg crate diffuser, aluminum or stainless steel optional.

These scientific instruments offers a wide area of application industries ranging from Micro-Electronics, Aerospace, Medical equipment and packaging. Modular Hardwall Clean rooms are also an excellent product for the Compounding Pharmacy market. Hard Wall Clean Room is constructed from components which can be changed in size and design and meet cleanliness levels from Class 100,000 to Class 10. Weiber Hardwall Cleanrooms are almost 100% reusable.

Weiber Modular Hardwall Cleanrooms are less expensive and can be installed in a fraction of the time. The clean Room has been designed and engineered with roof loading capabilities for mechanical and process equipment or storage, saving floor space. Modular Hardwall Cleanrooms are designed to provide clean environments of Class 100,000, Class 10,000, Class 1000 and Class 10 according to customer’s requirement.

Salient Features

Air Locks and Gowning Rooms

Modular and Prefabricated

ISO certified

High quality performance

Interior height of 8 to 16 ft

Clean Room spans upto 34 feet

Single pass or recalculating

Expandable and upgradable

Rigid wall, withstand high internal pressure.

Adjustable pressure upto 0.06 W.C.

T-Bar ceiling complete with integrated lighting and filtration

Interlocking 1.75" (44 mm) powder-coated square steel frame

Technical Specifications

Clean Rom Construction

Stainless Steel

Height

7 in.

Adjustable pressure

0.06W.C.

Modular width

4 in.

Rom Size

4 X 7 X 14 ft.

Sliding Door width

36, 48 and 60 in.

Entrance Door Size

45 X 93 in.

Filter

HEPA Filter 99.97% efficient

Types

Class 100,000 to Class 10

Wiring

Reloc Wiring System

Current Required

20 amp

|

|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

The Aluminum Bio-Clean Room is specifically designed to meet the requirements of the Medical and Pharmaceutical industries. The design of Aluminum Bio Clean Room equipment allows to be used as a totally free standing room, or in combination with the existing walls and, the ceiling. Weiber Aluminum Bio-Clean Room comes with completely factory prefabricated for minimal on-site installation time and is self contained with all components factory-finished. Average installation time is 2 to 3 days from start to certification. The Aluminum Bio-Clean Room design emphasizes particle infiltration as well microbial contamination protection.

The aluminum components are coated with a clean anodized finish. Weiber is the manufacturer and supplier of both standard and customized Bio Clean Room employing latest technology and high quality construction. The Bio Clean Room is designed and constructed room in which the air supply, air distribution, filtration of air supply, materials of construction, and operating procedures, are regulated to control airborne particle concentrations to meet appropriate cleanliness levels.

Weiber Aluminum Bio-Clean Room offers a major advantage over other clean room equipment is its ability to be enlarged or reduced without having to tear the entire room down. Each Aluminum Bio-Clean Room can also be outfitted with Class 100 work zones eliminating the need for Clean Benches/Hoods. It offers application in pharmaceuticals, automotive industry, semi conductor industry and electronic industry.

Salient Features

Modular and Prefabricated

High quality performance

Clean Room spans upto 34 feet.

Single pass or recirculating

Expandable and upgradable

Adjustable pressure upto 0.06 W.C.

Wall to wall and wall to ceiling coving

Aluminum backing angle

Internal corners

Silicone seal required

FDA approved & ISO certified

Technical Specifications

Interior height

8 – 14 feet Height

Adjustable pressure

0.06W.C.

Modular width

6 – 34 feet.

Rom Size

4 X 7 X 14 ft.

Sliding Door width

36, 48 and 60 in.

Entrance Door Size

45 X 93 in.

Filter

HEPA Filter 99.97% efficient

Types

Class 100,000 to Class 10

Wiring

Reloc Wiring System

Current Required

20 amp

Clean Rom construction

Aluminium

|

|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

Weiber Micro Clean Room laboratory equipment is a semi-rigid, modular, softwall cleanroom. This scientific equipment is designed around the concerns found in the medical industries for microbial contaminants as well as the more stringent airborne particulate requirements found in the Aerospace, Micro-Electronics, and Hi-Tech Markets addresses the need to remove particles from the air, it also has options that reduce or eliminate the chance of contamination from being introduced inside the room. All micro clean rooms are manufactured and tested under strict observation of renowned scientists and experts. These micro Clean Rooms offer wide area of application in automotive industry, semi conductor industry, electronic industry and pharmaceutical industry.

Weiber is a full-furnished clean Room manufacturing company to be used by various industries such as pharmaceutical, medical device, semiconductor, electronics, aerospace, bio-technology, food, cosmetic, nuclear, auto and nano-chip sectors nationwide. Weiber develops specialized Micro Clean Room equipment which complies with ISO standards improved quality and low cost. Weiber works to provide minimally intrusive cleanroom equipment testing and prompt results allows customers to satisfy the requirements of their cleanroom. Weiber offers certain protocols to their customers while entering into clean room. Weiber air shower offers unmatched design, prices, specifications and usages for researchers and scientists.

Salient Features

High quality performance

Scrub panel covered with white Formica.

High visual appeal.

Remove adhesive & residue.

Modular and Prefabricated

Single pass or recirculation

Expandable and upgradable

Rigid wall, withstand high internal pressure.

T-Bar ceiling complete with integrated lighting and filtration

Light Weight

Easy installation

Portable & Economical

FDA approved & ISO certified

Technical Specifications

Clean Rom construction

Stainless Steel

Interior height

8 – 14 feet Height

Adjustable pressure

0.06W.C.

Modular width

6 – 34 feet.

Room Size

4 X 7 X 14 ft.

Sliding Door width

36, 48 and 60 in.

Entrance Door Size

45 X 93 in.

Filter

HEPA Filter 99.97% efficient

Types

Class 100,000 to Class 10

Wiring

Reloc Wiring System

Current Required

20 amp

|