UBC scientists create cleaner method to produce rayon fibers

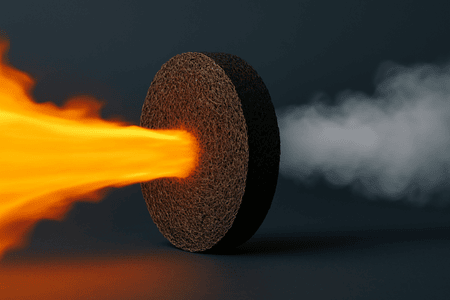

YarnsandFibers News Bureau 2025-12-04 14:46:21 – United KingdomA research team at the University of British Columbia has created a cleaner way to make rayon, a widely used fabric in clothing for over 100 years. This new process could greatly reduce chemical use and make textile production more sustainable.

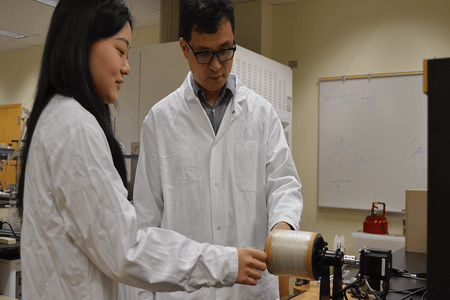

The study, led by UBC Forestry associate professor Dr. Feng Jiang and PhD student Huayu Liu, shows a method to spin continuous cellulose fibres without using the strong and harmful solvents normally required in commercial fibre making.

Dr. Jiang explained that synthetic cellulose fibres like rayon have been produced for more than 130 years. While the fibre itself is renewable and biodegradable, the methods used to make it are often toxic, energy-heavy and harmful to the environment. The team aimed to reduce these impacts significantly.

Because this method works with less processed pulp, it removes several steps that usually depend on bleaching or strong chemical treatments. This makes the full process simpler, cleaner and more environmentally friendly.

Dr. Jiang noted that the results are a real improvement. Creating synthetic cellulose fibre with fewer chemicals and much lower environmental impact is an important step forward, he said. Sustainability involves not only the final product but also careful sourcing of raw materials and ensuring the entire process avoids toxic solvents and reduces pollution.

So far, the fibers have been made only at a laboratory scale. The team is now looking for ways to increase production. They are working with Professor Stephanie Phillips at Kwantlen Polytechnic University’s fashion design school, where knitting and weaving tests will be carried out once they can produce larger amounts of fiber.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide