Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

Weiber manufactures paperless chart recorder Thermo Hygrograph to measure both temperature and humidity. Weiber Thermo Hygrograph is applicable in Libraries, Computer Rooms, Food and Paper Storage Areas, HAV and is used to control all climate-sensitive production processes in electronic data-processing centers, control cabinets, wind turbines, storage rooms and museums. The case of Electronic Thermograph is made up of clear plastic to enable data easily readable. Weiber offer Bimetalic Thermograph at most affordable prices.

It is an ideal equipment for textile labs in which the items to be tested like cotton etc are highly hygroscopic in nature. Weiber employs latest Technology Equipment with modern aesthetics.

Salient Features

The case is made of clear plastic so that data can be read easily without removal.

Disposable ink cartridge.

Printed circuit board has durable solid state electronics.

Recording paper charts are available in 1, 7, 31, 62 and 93 day cycles.

The durable, lightweight cylindrical aluminum drum turns clockwise on a direct gear drive.

Selection of a 1, 7, 31, 62 or 93 day cycle can be made with a push of the keypad

The upper range of the chart records temperature, the lower range records relative humidity.

Two Dry cell batteries installed underneath the bottom plate can power the unit for approximately one year of continuous use.

|

|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

Weiber Digital Anemometer is used to measure the wind speed and is a and is a common weather station instrument.. This instrument is portable, fast, has accurate reading, digital readability and has the convenience of a remote sensor separately. Weiber Anemometer is manufactured using latest techniques and quality raw material to provide efficient performance to the end users. It has data hold facility. It has multifunction display. It is used to measure wind velocity in the range of 0.4 to 30 m/s. It is hand held type and has Digits LCD Display. This device is especially suited for the measurement of low airspeeds. This instrument simultaneously measures and displays air velocity, temperature, humidity and Calculates CFM / CMM.

Weiber Digital Anemometer offers a wide area of application in Aircraft operators, Meteorologist and Power company technician. This anemometer is most useful, however, in strong, steady air streams, such as in wind tunnels and aboard aircraft in flight. Digital Anemometer manufactured by Weiber is an advanced device that is ideal for checking the air conditioning and heating systems. Its compact housing cabinet makes it convenient to use.

Salient Features

Double LCD digital display

Low power consumption

Easy-to use design

Highly sensitive

Compact housing cabinet

Accurate readings for high as well as low velocities of air

Built-in low battery indicator

Microprocessor circuit assures maximum possible accuracy.

|

|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

The material handling air showers from Weiber brand have been specifically designed to provide a contamination free working area for conducting routine experiments and studies. These energy efficient units are fully self-contained and well equipped to provide and sustain a highly sterile working environment. Our versatile air showers are quite adept at controlling the level of contamination for particle sensitive processes such as disc drive and semiconductor manufacturing, pharmaceutical drug testing and for research applications involving molecular biology and biochemical experiments, cell and tissue culture experiments etc.

Equipped with reset default function, auto reset feature and alarms and indicator lamps for open doors, fluctuations in set parameters and power failure, our air showers offer an unmatched ease of use that makes us the leading brand for laboratory equipments. The side flow air shower is easy to install and is operational with a simple plug-in to the power source. Our fully automatic air showers use microprocessor based controllers for highly accurate working conditions and LED display for ease of monitoring. The automatic reset feature automatically resets the equipment to a safe working level, thereby saving controller settings for smooth operation and preventing system failure and any accidental lock-outs. Weiber air shower design offers unmatched prices, specifications and usages for biotechnology lab and other laboratories.

Working principle of Material Handling Air Shower (Two side flow)

The material handling air showers from Weiber feature a highly efficient pre-filter assembly and HEPA filters with around 99.99% efficiency in removing particles as small as 0.3 microns in size. The air entering the enclosed chamber of an air shower passes through the top mounted pre-filter assembly comprising of fully washable, easy to clean poly fiber synthetic media of around 1’’ thickness and is then directed towards the HEPA filters made up of glass pleated filter media to eliminate dust particles and other particulate matters 0.3 microns in size or larger. The filtered air is then sprayed onto the personnel through top and side mounted jets and nozzles at appropriate face velocities to remove the dust and particulate matters from the skin surfaces and clothes of the person, prior to entering the clean room.

The two-way operation of our laboratory air showers allows the air showers to be activated in both the directions to prevent the release of hazardous substances from the controlled environment to the outside, while maintaining clean room conditions within the working chamber. Our two-way material handling industrial air showers are particularly useful in animal research laboratories and pharmaceutical industries for containment of harmful microbes and other hazardous substances. Since only one door can be opened at a time, the release of contaminating particles from the air shower cubicle is effectively controlled in both directions.

Efficiency of Material Handling Air Showers (Two side flow)

Though there has been some debate over the efficacy of air showers in maintaining clean room conditions in the past decades, the recent test data conclusively proves the efficiency and effectiveness of air showers in maintaining contamination-free working conditions. As indicated by the test results of a series of repetitive tests conducted by a Japanese company several years ago, the air showers can effectively remove up to 90% of the contaminating particles, drastically reducing the contamination levels for a controlled atmosphere.

Size

The material handling air showers from Weiber are available in both standard and customized sizes to suit individual customer requirements. The standard models offer an internal working space of 1.5mx1.5mx2m /2mx2mx2m/2.5mx2.5mx2m. Weiber is also a leading developer of customized air shower.

Construction Details

Our wooden air showers use extremely durable, heavy industrial grade wood and highly resistant and non-corrosive mica or high grade ss-304/ss-316 stainless sheets as construction materials. The internal surfaces of our mobile air showers are plastic laminated and available in attractive finishes. Both the doors feature an attractive aluminium panel and clear view glass/ acrylic panels.

The programmable solid state circuit control system located at the junction box of the unit allows programming of the operating conditions. The programmable microprocessor based system detects even the minutest fluctuations from the set parameters to ensure uniform and accurate working conditions throughout the working chamber. The control unit also allows the user to adjust the air nozzles for adjusting the air flow and face velocity to ensure optimum efficiency of the equipment. It also allows setting of the operation time from 0-9,990 seconds as per the requirements of specific applications.

High performance motor and blower assembly

The permanently lubricated centrifugal motors and blowers are well balanced statically and dynamically to ensure high performance. They conform to the national product standard and have ISI bearing. 39. The 21 CFR compliant air shower has been designed to produce least disturbance due to vibrations and noise levels, often below 60db and are quite energy efficient.

Filter assembly

Weiber clean room air showers come equipped with efficient and easy to clean pre-filters and HEPA filters for maintaining a contamination free working environment. The HEPA filters are up to 99.99% efficient in removing particles as small as 0.3 microns and the more efficient ULPA filters capable of removing smaller particles up to 0.1 microns in size are also employed to achieve a higher degree of sterility.

Indicator lamps and emergency switch

The indicator lamps alert the user in case of an unlocked or open door and the emergency switch unlocks both the doors instantly to prevent accidental lockouts.

Illumination system

Our steel air showers use top mounted fluorescent lights, concealed within a light panel, for adequate illumination of the working area. The lighting arrangement conforms to the US federal standards and provides a minimum illumination level of 800 lux.

Salient Features

Versatile and ergonomic design

Programmable operation

Low Noise And Vibration Levels

Conforms to US Federal Standard

Calibration & Protocol Documentation

Economical and energy efficient

|

|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

Our material handling air showers (tower flow) are enclosed chambers ideally installed in front of a clean room to prevent the entry of contaminating particles within the working area. The Clean room air showers are specifically designed for the elimination of surface particles from the materials, clothes and skin surfaces of the personnel, prior to entering a clean room or controlled environment chamber. Our material handling air showers find widespread use in semiconductor manufacturing units, animal research facilities, pharmaceutical production units, micro fabrication industry and in basic and applied research laboratories.

Working Principle of Material Handling Air Showers (Tower Flow)

Both the doors of our material handling Tower flow air showers are interlocked and magnetically operated. They are permanently energized and open instantly when the open door push button is pressed. Once the user enters the air shower cubicle, he/she can start the shower cycle from the inside. The shower cycle is programmable and can be set as per the requirements of the industry. Both the doors of the unit remain locked till the shower cycle continues, to prevent the entry of external contaminants while the air shower is operational. Once the Tower flow air shower cycle is completed, the personnel can exit through the exit door. The one-way mode of operation allows the user to enter the air shower cubicle, but he/she cannot exit through the entrance door, therefore controlling the traffic patterns into and out of the controlled environment chamber. Moreover, the pre-purge function of our modular air showers allows the unit to self-clean in a power-on mode. The pre-purge time is also programmable and can be set between 0-3 minutes. Air shower principle is based on subjecting the personnel through adequate velocity of clean air coming through a pre filter assembly.

The air present in the air shower cubicle is continuously circulated through the filter assembly, comprising of pre-filters and HEPA filters. The filter assembly physically entraps the contaminating particles and removes them from the air circulation. The efficient fans and blowers blow the filtered air into the air shower cubicle through adjustable nozzles at appropriate face velocities. The turbulent air streams produce enough shearing effect to loosen the dust particles and other particulate matters from the external surfaces, causing their wash down with the air stream. The air shower cubicle is maintained at a slightly higher pressure as compared to the outside to prevent the contaminating particles from entering the cubicle when the unit is at rest. Air Shower specifications are in accordance with the US Federal Standards.

Product Description

Filter assembly

Our quality control air showers are equipped with top mounted pre-filters and HEPA filters for the removal of particulate matters as small as 0.3 microns in size with a filtration efficiency of more than 99.97%. The pre-filters can effectively remove around 85% of the particulate matters, therefore reducing the contaminant load on the HEPA filters and increasing their efficiency and life span. The filtered air is released through adjustable nozzles, arranged in a uniform pattern on the walls and ceilings. The pre-filter unit is fully washable and is made up of non-woven synthetic polyester, whereas the easy to clean HEPA filters are made up of glass pleated non-woven fabric filter.

Control Unit

The unit is controlled through a programmable solid state circuit control system, located at the junction box of the unit. The junction box is a tamper proof enclosure that houses emergency setting buttons for switching off of the equipment in response to audio visual alarms. The control unit houses the operation timer and nozzle adjustment buttons. Our air showers use microprocessor based controllers for various set parameters and for the detection of any errors or deviations from the set parameters.

Construction Details

Our air showers use heavy industrial grade mica clad wooden boards and stainless steel (SS-304, SS-316) as construction materials. The internal surfaces are laminated and available in attractive finishes. The unit is provided with interlocked and magnetically operated doors on either side of the air shower cubicle. The doors are made of aluminium panels and have clear view glass/acrylic windows for increased visibility. The compartment access panels are made of aluminium panel and are hinged for ease of operation. Air shower room is a closed cubicle with adjustable nozzles air showers designed for clean room applications.

Motor And Blower Assembly

The motor and blower motors are statically and dynamically balanced and have permanently lubricated bearings for long lasting and trouble free operation. They bear ISI marking and are rated at 1/5 HP. The blower access panel is located at the side of the air shower unit.

Illumination

Our air showers use top mounted fluorescent lights for adequate illumination of the shower cubicle. The fluorescent lights panel is concealed at the upper portion of the unit and provides a minimum illumination of 800 lux. The lighting arrangement conforms to the US Federal standards.

Key Features

Versatile usage

Ergonomic design

Reduced vibration levels

Low noise level < 60 db

Programmable operation

Calibration and protocol documentation

Conforms to the US Federal Standards

Operating Features

Programmable mode of operation, pre-purge and shower time

Floor matting operated switch for sequential operation of the air shower

Fully washable pre-filters capable of removing around 85% of particulate matters

Highly efficient HEPA filters with around 99.99% filtration efficiency for removing particles as small as 0.3 microns and larger.

Both the doors are Interlocked and magnetically operated to prevent them from opening at the same time

The auto reset feature unlocks the doors to prevent accidental lockouts

The reset default function resets the program settings to default values

Microprocessor based controls for the set parameters’, detection of errors and their display

The clean room/grey room settings can be reversed via microprocessor based controllers, eliminating the need for physical reorientation of the unit.

Permanently lubricated direct drive centrifugal motors and efficient blowers capable of maintaining appropriate face velocities of the air (6000 ft/min + 20 feet)

Multidirectional air flow for better reachability

Emergency override buttons on both sides of the air shower to release the doors even when the air shower cycle has not completed

Indicator lights for open doors

LED indicators for interlock and shower sequence

An administrator PIN can be set to prevent unauthorized access to the air shower settings

A maintenance function operates the fan continuously for service checks and air velocity measurements

|

|

|

Acmas Technocracy Private Limited

|

Laboratory Machine For Textile

|

|

|

|

|

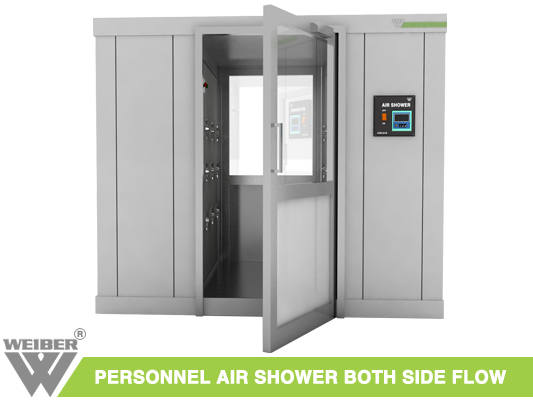

The air showers (personnel) from Weiber are fully self contained units, designed to provide complete decontamination solutions for various clean room applications. They are ideally installed at the entrance of a clean room or controlled environment chamber to minimize the entry of dust and particulate matters inside the clean room via the clothes and skin surfaces of the personnel. Our air showers feature programmable operating modes for flexible application and microprocessor based controller for precise supervision of the operating parameters. They use highly efficient pre-filters and HEPA filters for maintaining highly sterile working environments and an integrated fan/blower assembly to provide high velocity air streams for maximum scrubbing action against dust and particulate matters adherent on the exposed skin, clothes and material surfaces.

The unit allows both side flows, allowing the air showers to be activated in both the directions. The user can exit through the clean room door or the grey side door, without compromising the sanctity of the clean air environment. This mode of operation prevents the egress of harmful contaminants from the clean room to the outside environment, making the unit particularly useful in pharmaceutical industries, animal research laboratories and other applications that require working with harmful and biohazardous substances.

Our air showers are prefabricated, tested and pre-wired units, offering an unmatched ease of installation and use. The use of high quality construction materials provides a reliable and sturdy construction, whereas the microprocessor controller provides maximum application flexibility. Available in a wide range of modular designs, our air showers provide a cost effective solution to all the decontamination problems in routine clean room applications.

Key Features

Ergonomic design

Versatile usage

Clean, durable construction

Easy to install and operate

Available in both standard and customized configurations

Available with calibration protocol documentation and complete self-diagnostic systems

Programmable operation

GMP/GLP compliant systems

Designed to ensure minimum vibration and noise level < 60 db

Lighting arrangement conforms to the guidelines for US federal standards

Operating Features

Programmable operating modes

Solid state programmable microprocessor based controls for various operating parameters

Fully washable pre-filters remove around 85% of particulate matters, therefore reducing the load on HEPA filters and increasing their efficiency and life span

Highly efficient HEPA filters with around 99.99% filtration efficiency for removing particles as small as 0.3 microns and larger.

Floor matting operated switch for sequential operation of the air shower

Multidirectional air flow

Adjustable air nozzles

Permanently lubricated direct drive centrifugal motors and efficient blowers for maintaining appropriate face velocities of the air (6000 ft/min + 20 feet), while producing minimum vibrations and noise (less than 60 db). Rated at 1/5 HP

Thermally protected high efficiency motors reduce electrical load

Emergency buttons on both sides of the air shower to prevent accidental lock-outs

Indicator lights on both sides of the air shower for regulation of traffic within the cubicle

Interlocked doors minimize any chances of contamination

Door interlocks operate on the magnetic system

Hinged motor/blower compartment access panels made of coated aluminium

Tamper proof junction box, placed on top

Solid state LCD timer with tamper proof closure controls the shower operation

Emergency switch off button with audible alarm located within the shower cubicle

Applications

Microelectronics and semiconductor industries

Pharmaceutical industries

Biomedical research

Life Sciences

Aerospace industries

Spray painting

High precision manufacturing processes

|