Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Jiangyin Selen Chemical Fiber Equipments Co. Ltd.

|

Knitting Machine

|

|

|

|

|

CAPACITY:10 TO 100 MT PER DAY

RAW MATERIAL: PET BOTTLE FLAKE, PET POP CORN, LUMPS OR VIRGIN CHIPS.

PRODUCT: SOLID POLYESTER STAPLE FIBER (PSF) AND 3 DIMENSIONAL CONJUGATED FIBER(HCF)(INCLUDING DOPE DYED FIBER),THE SPECIFICATION FROM 15D TO 20D.

we have more than twenty years PSF production line production history and our production lines are running in more than 30 countries.We produce polyester staple fiber production line and provides installation,setting and maintaining service including used production line rebuilding.We can provide all spare parts,wearing parts as a professional factory with high quality and low price.The core part of the PSF Production Line is really important. The knowledge of how to run the line efficiently is mostly of the same importance. The training of the workers and the workers involvement in their skills and understanding in fiber production play an important role. Our company will provide a complete package of service and finally make sure the customer can operate the line and achieve high efficiency and quality production. Please contact us if you have any questions. Refer to more information on www.selenchina.com

Process flow of the production line

Fore spinning Line:

Vacuum Dryer -> Hopper -> Screw Extruder -> Filter -> Spin Beam (Meter Pump System, Spin Pack, Spinneret) -> Quenching Unit -> Interfloor Duct -> Draw-off Wall -> Capstan Roller -> Sunflower Gearing unit -> fiber can traverse system

After spinning Line:

If 2-Dimensional Hollow Fiber:

Can Creel -> Inlet Thread Guide -> Tow Guide Stand -> Dipping Bath -> 1st Draw Stand -> Draw Bath -> 2nd Draw Stand -> Draw Steam Chest -> 3rd Draw Stand -> Tow Stacker -> Crimper Steam Box -> Crimper -> Tow Conveyer -> Relaxer -> Tow Tension Stand -> Cutter -> Chain Plate Conveyor -> Baling Press

If 3-Dimensional Hollow Fiber:

Can Creel -> Inlet Thread Guide -> Tow Guide Stand -> Dipping Bath -> 1st Draw Stand -> Draw Bath -> 2nd Draw Stand -> Draw Steam Chest -> 3rd Draw Stand -> Tension Control Device -> Tow Stacker -> Crimper Steam Box -> Crimper -> Silicon Oil Sprayer -> Tow Tension Stand -> Cutter -> Fiber Spreader -> Fiber Leveler -> Relaxer -> Chain Plate Conveying system -> Baling Press

|

|

|

Jiangyin Selen Chemical Fiber Equipments Co. Ltd.

|

Knitting Machine

|

|

|

|

|

We are professional spun-bonded polypropylene nonwoven production line manufacturer, There are twenty years production of nonwoven production line of history with a number of professional technical staff and excellent processing equipment. In order to adapt to market competition, we cooperate with professional institutions and Scientific Research Institute in technical, improve product level of technological innovation, develop new high-tech products. The company produces good quality products and takes reasonable business purposes, continues to win the trust of customers and is recommended by users all over the country. Products are exported to more than 30 countries and regions and are well-known in plastic machinery industry market.

Nonwoven production line introduction

Main process flow of nonwoven production line:

Chip conveying → extrusion melting → filtering spinning → air draft → suction laying → Breza consolidation → cloth, cutting → wrapper library

Raw materials of nonwoven production line:

Using spinnable polypropylene (PP) slices, performance should meet the following requirements:

More information refer to www.selenchina.com

Non-woven production line main specification

A. annual 3000 tons/year (40 g/m2 per year 8000h)

B. product width 3200mm ,2400mm,1800mm

C. product specifications 10 ~ 160 g/m 2

D. single silk 1.5-2.5d

E. cloth maximum diameter 1000mm

F. < 1% of raw materials consumption

|

|

|

Jiangyin Selen Chemical Fiber Equipments Co. Ltd.

|

Knitting Machine

|

|

|

|

|

CAPACITY:10 TO 100 MT PER DAY

RAW MATERIAL: PET BOTTLE FLAKE, PET POP CORN, LUMPS OR VIRGIN CHIPS.

PRODUCT: SOLID POLYESTER STAPLE FIBER (PSF) AND 3 DIMENSIONAL CONJUGATED FIBER(HCF)(INCLUDING DOPE DYED FIBER),THE SPECIFICATION FROM 15D TO 20D.

we have more than twenty years PSF production line production history and our production lines are running in more than 30 countries. We produce polyester staple fiber production line and provides installation, setting and maintaining service including used production line rebuilding.We can provide all spare parts,wearing parts as a professional factory with high quality and low price.The core part of the PSF Production Line is really important. The knowledge of how to run the line efficiently is mostly of the same importance. The training of the workers and the workers involvement in their skills and understanding in fiber production play an important role. Our company will provide a complete package of service and finally make sure the customer can operate the line and achieve high efficiency and quality production. Please contact us if you have any questions. Refer to more information on www.selenchina.com

Process flow of the production line

Fore spinning Line:

Vacuum Dryer -> Hopper -> Screw Extruder -> Filter -> Spin Beam (Meter Pump System, Spin Pack, Spinneret) -> Quenching Unit -> Interfloor Duct -> Draw-off Wall -> Capstan Roller -> Sunflower Gearing unit -> fiber can traverse system

After spinning Line:

If 2-Dimensional Hollow Fiber:

Can Creel -> Inlet Thread Guide -> Tow Guide Stand -> Dipping Bath -> 1st Draw Stand -> Draw Bath -> 2nd Draw Stand -> Draw Steam Chest -> 3rd Draw Stand -> Tow Stacker -> Crimper Steam Box -> Crimper -> Tow Conveyer -> Relaxer -> Tow Tension Stand -> Cutter -> Chain Plate Conveyor -> Baling Press

If 3-Dimensional Hollow Fiber:

Can Creel -> Inlet Thread Guide -> Tow Guide Stand -> Dipping Bath -> 1st Draw Stand -> Draw Bath -> 2nd Draw Stand -> Draw Steam Chest -> 3rd Draw Stand -> Tension Control Device -> Tow Stacker -> Crimper Steam Box -> Crimper -> Silicon Oil Sprayer -> Tow Tension Stand -> Cutter -> Fiber Spreader -> Fiber Leveler -> Relaxer -> Chain Plate Conveying system -> Baling Press

|

|

|

HB Productions

|

Knitting Machine

|

|

|

|

|

Used Circular Knitting Machines for sale

8 Machines of Mayer & Cie 2006

Single jersey auto striper with lyca attachment and can be converted into 8 colors (diameter 30 & gage 20)

6 machines of Pai-Lung (2006)

Single jersey auto striper 6 color (Diameter 30 & gage 20 with 14 gage extra cylinder)

For further information contact Mr Hamza

0092-334-4444447

Video: http://www.youtube.com/watch?v=V2rO6rD6GH4&feature=youtu.be

|

|

|

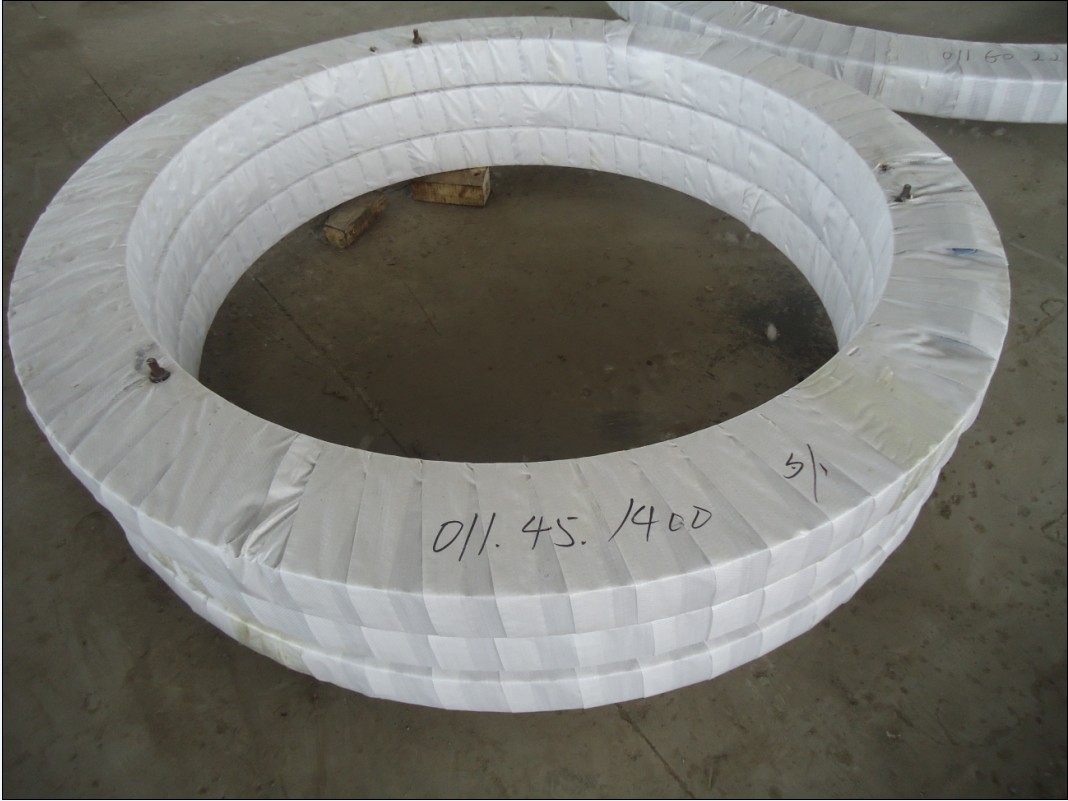

XD Slewing Ring Bearing Co., Ltd

|

Knitting Machine

|

|

|

|

|

No Gear

1275001, 12770001, 12775001, 12780001, 12785001, 12790001, 16289001, 16389001, 16290001, 16291001

Internal Gear

16292001, 16293001, 16294001, 16295001, 16296001, 16390001, 16374001, 16297001, 16298001, 16299001, 16300001, 16301001, 16302001, 16303001, 16304001

External Gear

16305001, 16306001, 16307001, 12440001, 16308001, 12288001, 16309001, 16310001, 16311001, 16312001, 16313001, 16314001, 16315001, 16316001, 16317001

|