Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Changshu Chemical Fiber Equipment

|

Knitting Machine

|

|

|

|

|

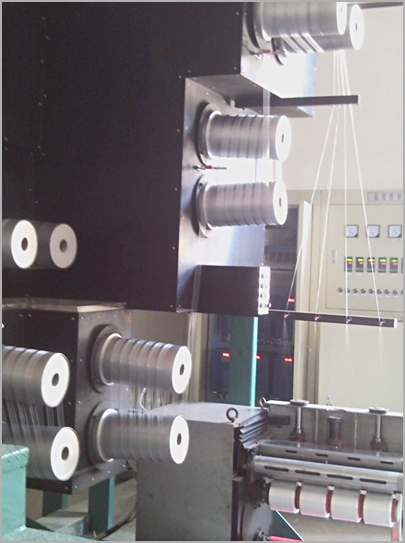

Main features of PP FDY spinning machine

Number of machine parts of PP FDY spinning machine: 1、2、4

Spinner distance of positions of PP FDY spinning machine: 1200~2000mm

Number of spinning heads per position of PP FDY spinning machine: 2、4、6、8

Fineness of products of PP FDY spinning machine: 180D~2100D

Screw diameter of PP FDY spinning machine: Φ30mm~Φ120mm

Drafting roller size of PP FDY spinning machine: Φ190×330mm or Φ180×280mm

Winding speed of PP FDY spinning machine: 1500~3000m/min

PP FDY spinning machine applicable winding machine: A435, A635, A835

Main features:

Use the lengthened screw extrude and AC inverter controlled motor.

Use the new type of spinning box and mixing melt pipeline.

Use the big board of spinneret, and install the round or the rectangular on the seal components.

Use the accurate measurement of the planet gear pump extension quick release transmission rod.

Use the stable quenching unit device and large capacity spray oil system.

Use the environmental production and energy saving medium electrical heating system and the imported intelligent instruments control device.

Use the 3~5 draft roller to draft the tow and heat setting, and equip with new device of network.

Use the domestic automatic switching take-up machine.

Retrofit the edge renewal changing filter and use the recycling production of material to produce the upjohn filament.

The quality assurance of high tenacity fiber is above 7g/denier.

|

|

|

Changshu Chemical Fiber Equipment

|

Knitting Machine

|

|

|

|

|

Main features of Nylon FDY spinning machine

Number of machine parts of Nylon FDY spinning machine: 1、2、4

Spinner distance of positions of Nylon FDY spinning machine: 1200~2000mm

Number of spinning heads per position of Nylon FDY spinning machine: 2、4、6、8

Fineness of products of Nylon FDY spinning machine: 180D~2100D

Screw diameter of Nylon FDY spinning machine: Φ30mm~Φ120mm

Drafting roller size of Nylon FDY spinning machine: Φ190×330mm or Φ180×280mm

Winding speed of Nylon FDY spinning machine: 1500~3000m/min

Nylon FDY spinning machine applicable winding machine: A435, A635, A835

Main features:

Use the lengthened screw extrude and AC inverter controlled motor.

Use the new type of spinning box and mixing melt pipeline.

Use the big board of spinneret, and install the round or the rectangular on the seal components.

Use the accurate measurement of the planet gear pump extension quick release transmission rod.

Use the stable quenching unit device and large capacity spray oil system.

Use the environmental production and energy saving medium electrical heating system and the imported intelligent instruments control device.

Use the 3~5 draft roller to draft the tow and heat setting, and equip with new device of network.

Use the domestic automatic switching take-up machine.

Retrofit the edge renewal changing filter and use the recycling production of material to produce the upjohn filament.

The quality assurance of high tenacity fiber is above 7g/denier.

|

|

|

changzhou xingyi textile machinery factory

|

Knitting Machine

|

|

|

|

|

stainless steel

smooth eyes and surface

long time service life

|

|

|

Jiangyin Selen Chemical Fiber Equipments Co. Ltd.

|

Knitting Machine

|

|

|

|

|

The plastic recycling line is used to wash recycled plastic, and belongs to environmental protection field. The recycling line is used to crush, separate and wash the waste plastic, which solves the problem of dealing waste plastic.

Operation principles: baled materials dispersed by debaler firstly, then sorted by workers on sorting table, the granulator crushes sorted materials into pieces. Wrappers are separated from the pieces by cyclone separator, then the spinner washes and dries the pieces. Pieces sorted by float sink separator again, then the washed pieces will be divided.

The plastic recycling line is specialized in separating, washing and recycling wasted plastic. It can produce 2T per hour, and it can separate out clean PET/PP/PS/ABS/PVC/PE and so on. The maximum baling weight is 1000kg/bale.

More information refer to www.selenchina.com

|

|

|

Jiangyin Selen Chemical Fiber Equipments Co. Ltd.

|

Knitting Machine

|

|

|

|

|

CAPACITY:10 TO 100 MT PER DAY

RAW MATERIAL: PET BOTTLE FLAKE, PET POP CORN, LUMPS OR VIRGIN CHIPS.

PRODUCT: SOLID POLYESTER STAPLE FIBER (PSF) AND 3 DIMENSIONAL CONJUGATED FIBER(HCF)(INCLUDING DOPE DYED FIBER),THE SPECIFICATION FROM 15D TO 20D.

we have more than twenty years PSF production line production history and our production lines are running in more than 30 countries.We produce polyester staple fiber production line and provides installation,setting and maintaining service including used production line rebuilding.We can provide all spare parts,wearing parts as a professional factory with high quality and low price.The core part of the PSF Production Line is really important. The knowledge of how to run the line efficiently is mostly of the same importance. The training of the workers and the workers involvement in their skills and understanding in fiber production play an important role. Our company will provide a complete package of service and finally make sure the customer can operate the line and achieve high efficiency and quality production. Please contact us if you have any questions. Refer to more information on www.selenchina.com

Process flow of the production line

Fore spinning Line:

Vacuum Dryer ->Hopper ->Screw Extruder ->Filter ->Spin Beam (Meter Pump System, Spin Pack, Spinneret) ->Quenching Unit ->Interfloor Duct ->Draw-off Wall ->Capstan Roller ->Sunflower Gearing unit ->Fiber can traverse system

After spinning Line:

If 2-Dimensional Hollow Fiber:

Can Creel ->Inlet Thread Guide ->Tow Guide Stand ->Dipping Bath ->1st Draw Stand ->Draw Bath ->2nd Draw Stand ->Draw Steam Chest ->3rd Draw Stand ->Tow Stacker ->Crimper Steam Box ->Crimper ->Tow Conveyer ->Relaxer ->Tow Tension Stand ->Cutter ->Chain Plate Conveyor ->Baling Press

If 3-Dimensional Hollow Fiber:

Can Creel ->Inlet Thread Guide ->Tow Guide Stand ->Dipping Bath ->1st Draw Stand ->Draw Bath ->2nd Draw Stand ->Draw Steam Chest ->3rd Draw Stand ->Tension Control Device ->Tow Stacker ->Crimper Steam Box ->Crimper ->Silicon Oil Sprayer ->Tow Tension Stand ->Cutter ->Fiber Spreader ->Fiber Leveler ->Relaxer ->Chain Plate Conveying system ->Baling Press

|