Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Adasen Trade Compnay

|

Conveying Systems

|

|

|

|

|

Detailed Product Description

1 save energy/efficient

2 fast peanut roasting machine

3 continuous conveyor belt baking machine

4 easy to control

Continuous coffee beans Roasting Baking Equipment Features:

Microwave is electromagnetic waves which frequency from 300 MHZ to 300000 MHZ. Water molecule of heating medium material is polar molecule, its polarity orientation of the electric field with changes caused by the movement of molecules under high rapid frequency electromagnetic field changes, cause the numerator movement and the friction effect of each othe. Microwave field can field at this time into medium heat, make temperature of material increase, produce and popped a series of materialization process to reach the purpose of microwave heating dry.

Microwave industrial tunnel baking and puffing equipment, roasting equipment, microwave baking equipment,continuous microwave roasting machine,industrial microwave raosting baking machine , drying and sterilization machinery, widely used in the peanuts ,sesame seeds, wheat, melon seeds, peanuts, corn, soybeans, walnuts, almonds, chestnuts, pistachios, cashews and dried fruit etc baking.Compared with the traditional production methods, microwave baking foods are crispy and delicious, puffed full of particles, natural color, beautiful appearance, and has insecticidal sterilization.

Microwave industrial tunnel equipment baking characteristics - high energy conversion efficiency, fast heating.Microwave oven does not heat itself, but the microwave energy penetrate the material, the friction between the polar molecules within the material and produce internal heat.Make the internal liquid of processed material vaporize instantly ,pressurized expansion;and rely on the expansive force of gas,make polymer components structure degenerate,and become a network organization structure characteristics, stereotypes microporous substances.

1 While microwave equipment baking, along with the bactericidal effect. Microwave sterilization reflect in the dual role of thermal effects and non-thermal effects , compared to the conventional temperature sterilization ,can obtain a satisfactory sterilization in lower temperatures and a very short time.The sterilization temperature is around 80°C in general,the processing time is 3~5 minutes,and can maintain its nutrients.

2 Easy to operate. Microwave power and the conveyor speed can be sleepless adjustment, there is no thermal inertia, can open and stop at an time, easy to control,improve the production environment.Microwave equipment, no waste heat radiation, no dust, no noise, no pollution, easy to implement the testing standards of food hygiene.

3 The puffing effect is obvious. The purpose of rapid microwave heating effect, make the material internal water molecules vaporize rapidly,then reach the purpose of puffing.

4 Low-temperature sterilization, less loss of nutrients.Retain vitamin C,conventional heating treatment for fruits and vegetables is 46% ~ 50%, but the microwave can reach 60%~90%.Retain vitamin A,conventional heating treatment is 58%,but the microwave can reach 84%,and does not affect the original flavor, is a good method for deep processing of fruits&vegetables and get green foods.

If you are interested in our equipment- Continuous type microwave machine ,please feel free to contact us.Welcome to your sooner inquiry.

Thank you

Jinan Adasen Trade.,Ltd

Linda Fu

Tel:86-531-88976080 Mobel:+86 18369216482

Fax:86-531-88975500

QQ:2909036273

Skype:linda.fu5

|

|

|

Adasen Trade Compnay

|

Conveying Systems

|

|

|

|

|

Detailed Product Description

Tunnel Microwave Sterilization drying equipment

1.heating rapidly and uniformity

2.energy-saving and efficient

3.easy to co

Tunnel Microwave Sterilization drying equipment

Definition:

Conventional heating such as flame, hot air, steam drying is using the principle of heat conduction, the heat

from the material external incoming internal, gradually increase the center temperature of the object, called

the external heating.The center part to reach the needed temperature requires a certain amount of time,

poor heat conductivity objects requires longer time. The time of these traditional methods of drying is longer,

larger power consumption, heating is not uniform, flip up and down, large labor intensity, and microwave drying characteristics, microwave energy can penetrate the material, inside and outside can be heated at the same

time, the frequency is 2450MHZ, with every second 2400000000 5 ten million second oscillation, water

molecules are the same is a million times oscillation, molecular mutual friction, then the heat produced. So

self heating

Technical parameters

Power supply

380V±10% 50HZ±1% three-phase five-wire

Microwave Output Frequency

2450±50MHz

Microwave input apparent power

42KVA

Microwave output power

30KW

Microwave power adjustment range

0-30KW(adjustable)

Ambient temperature

-5-40°C

Dehydrate

30kg/h

Relative humidity

80%, Surrounding environment:no corrosive gas, conductive dust

and explosive gas

Overall dimension(L*W*H)

10680*820*1750mm

Transmission speed

0-10m/min(adjustable)

Height of the inlet and outlet

60 mm

Microwave leak

accord with a country GB10436-89 standards(<5 mw/cm^2)

Equipment safety

accord with GB-5226Electrical safety standard

accord with a country GB16798-1997 Food machinery health security index

Microwave heating and drying, sterilization characteristics:

1.Heated rapidly, uniformly

Without heat conduction process, in an instant it can penetrate into the material is heated, the penetration depth of a few centimeters or even tens of centimeters, seconds to minutes microwave into heat. Microwave selective heating, and will allow more uniform heating.

2.Efficiently

Material containing moisture can easily absorb microwave heat, therefore, almost no other losses in addition to a small amount of transmission loss. Microwave heating compared with the far-infrared heating, saving energy 1/3 to 2/3.

3Anti-virus sterilization preservation

Microwave heating with thermal effects and biological effects, therefore, at lower temperatures, anti-virus bacteria and bacteria; can save the material activity and food vitamins, color and nutrients.

4.Advanced technology, continuous production

As long as the microwave power to heat or to terminate. Transmission system to ensure continuous production, saving capabilities.

5. safe

The microwave energy is to control the metal is heated indoor wave tube work, microwave leakage is effectively suppressed. Radiation hazards and harmful emissions, does not produce waste heat, neither contaminate food, do not pollute the environment

6 Devices, covering the improvement of working conditions

If you are interested in our equipment- Continuous type microwave machine ,please feel free to contact us.Welcome to your sooner inquiry.

Thank you

Jinan Adasen Trade.,Ltd

Linda Fu

Tel:86-531-88976080 Mobel:+86 18369216482

Fax:86-531-88975500

QQ:2909036273

Skype:linda.fu5

|

|

|

Adasen Trade Compnay

|

Conveying Systems

|

|

|

|

|

Detailed Product Description

fruits microwave equipment for drying and sterilizing

1.Dry and Sterilization

1.Heating Rapidly and Uniformity

2.Energy Sa

microwave drying&sterilization machine-industrial microwave equipment

Specifications

This machine fits for drying and sterilizing powders , granular , sheet-like or gel-like food, and additive, flavoring, medicine,raw material of herbal medicine,nutritional health products,agricultural&sideline products,non-fired(or oil saving)instant noodles,noodles, rice powder noodles,soy products,beef jerky,preserved meat,dried fish,tea,tobacco and so on;and for drying,peeling and baking almond,peach kernel,groundnut kernels,chestnut and so on;and for puffing of leisure food,pachyrhizus chips,potato chips,dried shrimps,fish maw and so on;and for sterilizing and oral liquor,pickles,a variety of small packaging food;and for thawing the frozen fish, poultry;and for drying beans;and for drying and desulfurating and deoxidizing the metallurgical chemical products:such as oxalate cobalt,sulfur powder,mid ammonium tungstate,nickel hydroxide ,bluestone,iron,core,magnetic boards.disk,alveolate ceramic,glass,chemical fiber,cotton yarn,wood,leather,bamboo products, insulation materials, building materials,wood,cork,alveolate,cardboard,corrugated cardboard,and so on.

FEATURES:

1.Dry and Sterilization

1.Heating Rapidly and Uniformity

2.Energy Saving and Efficient

3.Technology Advanced

1.Fast heating. Microwave heating is completely different with traditional heating mode. It makes heating medium become heater, do not need heat transfer process. Although thermal conductivity is poor materials, also can achieve heating temperature in a very short time.

2.Save energy and efficiency. Because materials contain water absorb microwave easily and fever, so in addition to a small amount of transmission loss outside, almost no other loss, so high thermal efficiency, save energy.

3.Heating even. No matter how shape of each part of the body, microwave heating all can make the object and evenly infiltration and electromagnetic wave list to produce the heat. So heating good uniformity, won't appear the endogenous phenomenon focal.

4.Mouldproof, sterilization, fresh. Microwave heating has thermal and biological effect, can sterilize and mould proof in low temperature. Due to heating rapidly, the time is short, can maximum limit save material activity and the vitamin original colour and lustre and nutrition of food.

5.Craft is advanced, control easily. Microwave heating just have the basic conditions of water, electricity, as long as control power, can realize microwave heating or terminate immediately, use microwave equipment can process automation control of heating process and heating process specification.

6.Covers less area, safety and harmless. Because microwave can be controlled in made of metal heating indoor and wave, so microwave leak is few, no radiation hazards and harmful gases, do not produce the waste heat and dust pollution; Neither polluting food, also do not pollute the environment

If you are interested in our equipment- Continuous type microwave machine ,please feel free to contact us.Welcome to your sooner inquiry.

Thank you

Jinan Adasen Trade.,Ltd

Linda Fu

Tel:86-531-88976080 Mobel:+86 18369216482

Fax:86-531-88975500

QQ:2909036273

Skype:linda.fu5

|

|

|

Adasen Trade Compnay

|

Conveying Systems

|

|

|

|

|

Detailed Product Description

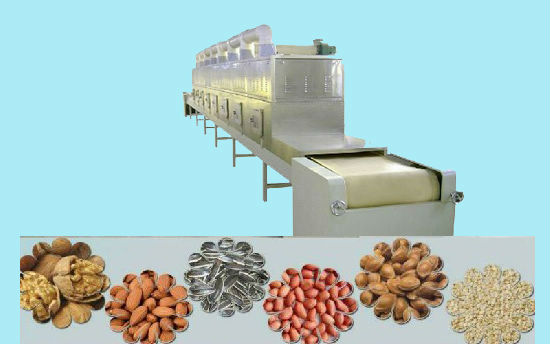

nuts roasting machine

1,fast drying

2,low energy cost

3,safe and clean

4.keep original nutrition.taste

nuts roastingmachine

Application

During recent years, microwave technology has been widely used for the fast drying of peanut, sesame, melon seeds, walnuts, almonds, chestnuts, etc.

Compared to the traditional drying method, the products dried by microwave are delicious, crispy, with particles fully puffed, natural color, intense flavor, fine shape, and sterilized and pesticided.

Characteristics

The quality, productivity, and hygiene condition of the finished products have have got complete promotion by the use of our microwave equipment.

1, Fast drying speed, perfect drying effect, good taste, and hygienic.

2, High thermal efficiency, without additional thermal loss

3, Easy to control, flexible

4, energy saving, heating uniformly

5, Low temperature sterilization can maintain the original color, smell, and taste

6,Automatic control, continuous production and enhance the economic benefits.

7,Microwave can also has sterilizing and mould proofing effect. The shelf life of the material can largely be extended but the reliance on preservatives is reduced.

8,Safe, clean, hygienic and protects environment. it is up to GMP standard. The high quality raw materials with careful design and manufacture can guarantee the microwave leaking amount conforms to the national standard. The stainless steel oven does not pollute the material.

Composition and microwave parts Automatic temperature control system, automatic microwave density control system, automatic alarm system, transmission correction system, transmission frequency control system, PLC control system, microwave magnetron with Panasonic, LG Brand, water cooling or wind cooling transformer(optinal), etc. This ensures that the equipment can work continuously for 24 hours.

parameter values

Brand Name adasen

Model Number JN-30

Production Capacity 35kg

Dryer&sterilizer microwave

Power input 42KVA

Power output 30KW

sterilization Capacity 300-360 kg/h

If you are interested in our equipment- Continuous type microwave machine ,please feel free to contact us.Welcome to your sooner inquiry.

Thank you

Jinan Adasen Trade.,Ltd

Linda Fu

Tel:86-531-88976080 Mobel:+86 18369216482

Fax:86-531-88975500

QQ:2909036273

Skype:linda.fu5

|

|

|

Adasen Trade Compnay

|

Conveying Systems

|

|

|

|

|

Detailed Product Description

1.heating rapidly and uniformity

2.energy-saving and efficient

3.proofing sterilization freshing

4 advanced craft

Cherry wood/basswood Microwave drying equipment for paper&wood

Used for bamboo, wood(pencil board,wood floor,hanger), red wingceltis, old mahogany, ebony, cherry wood, basswood, birch, teak, ormosia henryi, black walnut, oak, boxwood, pear wood, water cyclobalanopsis, SangMu,, serpentine wood, birch, maple spruce, pine, hemlock, cercis, jacaranda, sophora japonica, maple wood, poplar, maple, HuangTong, Holly, ginkgo biloba wood, camphorwood, fir drying insecticide;and for straw products, paper,paper bag board, honeycomb paper, corrugated paper,veneer drying insecticide;and for root carving whole drying, etc.

If you are interested in our equipment- Continuous type microwave machine ,please feel free to contact us.Welcome to your sooner inquiry.

Thank you

Jinan Adasen Trade.,Ltd

Linda Fu

Tel:86-531-88976080 Mobel:+86 18369216482

Fax:86-531-88975500

QQ:2909036273

Skype:linda.fu5

|