Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Jiangsu Aoshen Hi-tech Materials Co., LTD

|

Other Fibers

|

Raw

|

Flame Retardant

|

|

|

The polyimide fiber products have good mechanical properties and excellent properties of high temperature resistance, flame retardance, thermal insulation, anti-bacteria, radiation resistance and decay resistance.

ASPI® Product Performance

General index of ASPI® polyimide fiber

No. Items Unit Index

1 Fineness dtex 1.5~5

2 Density g/cm3 1.41

3 Breaking strength cN/dtex >4.0

4 Elongation at break % 10~30

5 Continuous use temperature ℃ 260

6 Decomposition temperature ℃ 560

7 Limiting oxygen index(LOI) % 38

8 Acid resistance Good

9 UV radiation resistance Good

ASPI® Product Application

(1)High temperature filter

The ASPI® polyimide fiber can be long-term used in 260℃.It has excellent properties of high temperature resistance, dimensional stability and chemical stability. As high temperature flue gases dedusting filter material, it is widely used in cement plants, coal-fired power plants, steel plants, refuse destructor plants, metal smelting factories and chemical plants, etc.

(2)Protective Fabric

The limiting oxygen index of ASPI® polyimide fiber is 38%. The fiber carbonizes and extinguish right after being deviated from fire, without melting and dropping. The combustion smoke is non-toxic. The fabric, made by ASPI® polyimide fiber, can keep good mechanical property and dimensional stability under the environment of high (low) temperature. The fabric has good thermal oxidation resistance, corrosion resistance and ultraviolet resistance and can be used as protective cloth for:

Firefighter, Petrochemical industry, Metallurgy industry, Boiler operator protective clothing, Fire resistance decorative material

(3)Fire resistant and heat insulation material

Because of the excellent high temperature resistance and outstanding manufactur ability, ASPI® polyimide fiber can be used to manufacture felt belts, felt roller for:

1) High temperature aluminum transportation (outlet of the aluminum extruder)

2) Glass tempering furnaces Outlet of for transportation rollers

3) Heat-insulating layer of engine and so on

(4)Insulating and composite material

ASPI® polyimide chopped fiber is suitable for manufacturing special polyimide paper. Due to the excellent thermal stability, flame retardant, electric insulation, mechanical performance, chemical stability, irradiation resistance properties of polyimide fiber, polyimide paper can be used for the insulation of H, C class motor and dry-type transformer, electrical insulation and honeycombed structure material. The honeycombed structure material is widely used as light-weighting lumber of radome, cabin, and aerospace.

|

|

|

Jiangsu Aoshen Hi-tech Materials Co., LTD

|

Other Fibers

|

Raw

|

Flame Retardant

|

|

|

ASPI® is the registered trademark of polyimide fibers which is manufactured by Jiangsu Aoshen Hi-tech Material Co., Ltd. The polyimide fiber products have good mechanical properties and excellent properties of high temperature resistance, flame retardance, thermal insulation, anti-bacteria, radiation resistance and decay resistance.

ASPI® Product Performance

General index of ASPI® polyimide fiber

No. Items Unit Index

1 Fineness dtex 1.5~5

2 Density g/cm3 1.41

3 Breaking strength cN/dtex >4.0

4 Elongation at break % 10~30

5 Continuous use temperature ℃ 260

6 Decomposition temperature ℃ 560

7 Limiting oxygen index(LOI) % 38

8 Acid resistance Good

9 UV radiation resistance Good

ASPI® Product Application

(1)High temperature filter

The ASPI® polyimide fiber can be long-term used in 260℃.It has excellent properties of high temperature resistance, dimensional stability and chemical stability. As high temperature flue gases dedusting filter material, it is widely used in cement plants, coal-fired power plants, steel plants, refuse destructor plants, metal smelting factories and chemical plants, etc.

(2)Protective Fabric

The limiting oxygen index of ASPI® polyimide fiber is 38%. The fiber carbonizes and extinguish right after being deviated from fire, without melting and dropping. The combustion smoke is non-toxic. The fabric, made by ASPI® polyimide fiber, can keep good mechanical property and dimensional stability under the environment of high (low) temperature. The fabric has good thermal oxidation resistance, corrosion resistance and ultraviolet resistance and can be used as protective cloth for:

Firefighter, Petrochemical industry, Metallurgy industry, Boiler operator protective clothing, Fire resistance decorative material

(3)Fire resistant and heat insulation material

Because of the excellent high temperature resistance and outstanding manufactur ability, ASPI® polyimide fiber can be used to manufacture felt belts, felt roller for:

1) High temperature aluminum transportation (outlet of the aluminum extruder)

2) Glass tempering furnaces Outlet of for transportation rollers

3) Heat-insulating layer of engine and so on

(4)Insulating and composite material

ASPI® polyimide chopped fiber is suitable for manufacturing special polyimide paper. Due to the excellent thermal stability, flame retardant, electric insulation, mechanical performance, chemical stability, irradiation resistance properties of polyimide fiber, polyimide paper can be used for the insulation of H, C class motor and dry-type transformer, electrical insulation and honeycombed structure material. The honeycombed structure material is widely used as light-weighting lumber of radome, cabin, and aerospace.

|

|

|

Jiangsu Aoshen Hi-tech Materials Co., LTD

|

Other Fibers

|

Flocked

|

Flame Retardant

|

|

|

ASPI® is the registered trademark of polyimide fibers which is manufactured by Jiangsu Aoshen Hi-tech Material Co., Ltd. The polyimide fiber products have good mechanical properties and excellent properties of high temperature resistance, flame retardance, thermal insulation, anti-bacteria, radiation resistance and decay resistance.

ASPI® Product Performance

General index of ASPI® polyimide fiber

No. Items Unit Index

1 Fineness dtex 1.5~5

2 Density g/cm3 1.41

3 Breaking strength cN/dtex >4.0

4 Elongation at break % 10~30

5 Continuous use temperature ℃ 260

6 Decomposition temperature ℃ 560

7 Limiting oxygen index(LOI) % 38

8 Acid resistance Good

9 UV radiation resistance Good

ASPI® Product Application

(1)High temperature filter

The ASPI® polyimide fiber can be long-term used in 260℃.It has excellent properties of high temperature resistance, dimensional stability and chemical stability. As high temperature flue gases dedusting filter material, it is widely used in cement plants, coal-fired power plants, steel plants, refuse destructor plants, metal smelting factories and chemical plants, etc.

(2)Protective Fabric

The limiting oxygen index of ASPI® polyimide fiber is 38%. The fiber carbonizes and extinguish right after being deviated from fire, without melting and dropping. The combustion smoke is non-toxic. The fabric, made by ASPI® polyimide fiber, can keep good mechanical property and dimensional stability under the environment of high (low) temperature. The fabric has good thermal oxidation resistance, corrosion resistance and ultraviolet resistance and can be used as protective cloth for:

Firefighter, Petrochemical industry, Metallurgy industry, Boiler operator protective clothing, Fire resistance decorative material

(3)Fire resistant and heat insulation material

Because of the excellent high temperature resistance and outstanding manufactur ability, ASPI® polyimide fiber can be used to manufacture felt belts, felt roller for:

1) High temperature aluminum transportation (outlet of the aluminum extruder)

2) Glass tempering furnaces Outlet of for transportation rollers

3) Heat-insulating layer of engine and so on

(4)Insulating and composite material

ASPI® polyimide chopped fiber is suitable for manufacturing special polyimide paper. Due to the excellent thermal stability, flame retardant, electric insulation, mechanical performance, chemical stability, irradiation resistance properties of polyimide fiber, polyimide paper can be used for the insulation of H, C class motor and dry-type transformer, electrical insulation and honeycombed structure material. The honeycombed structure material is widely used as light-weighting lumber of radome, cabin, and aerospace.

|

|

|

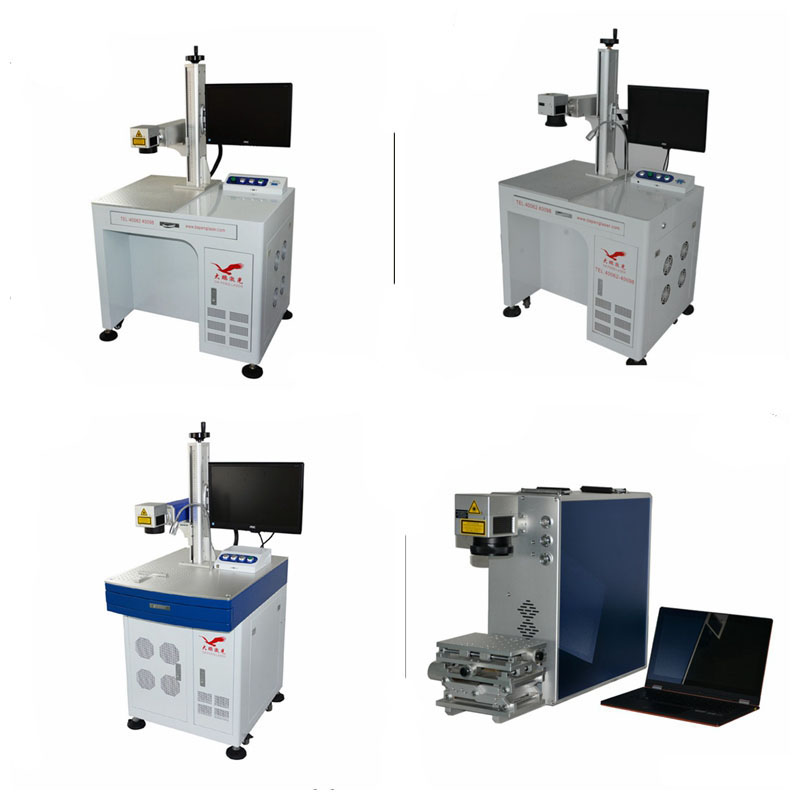

Shenzhen Dapeng Laser Technology Co., Ltd

|

Other Fibers

|

Others

|

Eco – Friendly

|

|

|

Model YLP-F10/20/30

Laser Power: 10W,20W,30W

Wavelenth: 1064nm

Standard Marking Area: 100mm*100mm

Optional Marking Area: 160mm*160mm,200mm*200mm

Marking Speed: ≤7000mm/s

Minimum Line Width 0.02mm

Minimum letter English: 0.2 x 0.2mm

Marking Depth 0 ~0.5mm

Location precision ≤0.01mm

Resetting positioning accuracy 0.002

Beam Quality M2:1.2~1.8

Electrical Requirements: Ac220V±10%.50HZ.5Amp

Cooling mode Air cooled

Scan Head High Precision Digital Scan Head

Unit Power <0.5kw

Operational Temp Range 10-40C

Operational Humidity Range 5%-75%, Non-condensing

Warranty: 2 years on laser source

Dimensions: 25*60*80MM

Net Weight 38KG

|

|

|

Technical Absorbents

|

Other Fibers

|

Raw

|

Others

|

|

|

This is one of our standard short staple fibre grades. It provides good balance of gel quality and absorbency properties, particularly under load and is suitable for a wide range of applications. Absorbency g/g:

15 Minute Free Swell Capacity (0.9% Saline) 47;

15 Minute Free Swell Capacity (DM) >140;

0.3 psi Absorption Under Load (0.9% Saline) 22;

0.3 psi Absorption Under Load (DM) >45;

|