Unwind3D unveiles advanced technology for 3D composite parts

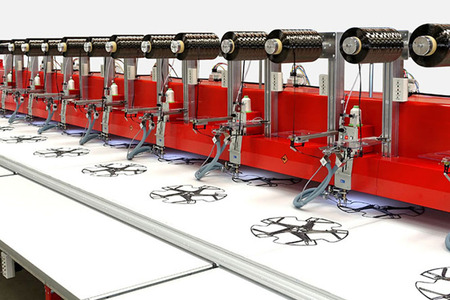

YarnsandFibers News Bureau 2025-07-07 15:57:11 – ItalyUnwind3D, a company located in Arsago Seprio, Italy, has created its own moulding cell technology using tailored fibre placement (TFP). This new system allows for more precise shaping of layered fabric into three-dimensional composite parts.

This new advancement is an important move toward making TFP more versatile. It introduces a high-performance moulding setup that works well with both thermoplastic and thermoset materials.

The custom-designed moulding system is made to manage the difficulties of forming thermoplastic composites, turning flat TFP shapes into strong 3D parts. In contrast to older methods, TFP thermoplastics often shrink when heated, which causes issues with pressure control, even heating, and tool setup.

Unwind3D has successfully solved these problems and is now making medium-sized batches of thermoplastic parts that are both strong and accurate in shape. Their moulding cells have proven their reliability, operating for nine hours daily over a ten-month period in a customer’s production line.

These fully automatic production systems cut down on manual work and ensure consistent results. Smart control of pressure and energy helps lower running costs while keeping performance high.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide