Researchers find bagworm silk outshines spider silk

YarnsandFibers News Bureau 2025-07-30 16:10:40 – JapanJapan’s National Agriculture and Food Research Organization (NARO) and Kowa, a company active in pharmaceuticals, optics, and textiles, have found that silk from bagworms actually performs better than spider silk in terms of durability.

According to their findings published in Nature Communications, bagworm silk is about 2.3 times tougher, meaning it can stretch and bend more without breaking, and has around 1.8 times the tensile strength compared to spider silk.

“Bagworm silk is protein-based, just like silkworm and spider silk,” said Asanuma Akimune, senior manager at Kowa’s Future Business Development Office. “Its strength comes from its well-structured arrangement of amino acids.”

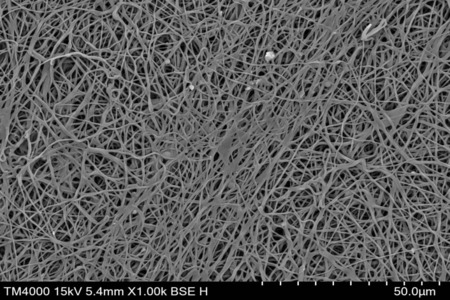

To bring this powerful fiber into practical use, Kowa set up a new research lab in Tsukuba City, Ibaraki Prefecture, and began joint research with NARO to breed bagworms artificially. Bagworms create a unique zigzag silk pattern they use as support for movement. Inspired by this, Kowa created extremely thin, nonwoven fabric-like sheets from the silk, achieving an annual production rate of about 1,000 square meters.

In November 2024, Kowa launched its Minolon brand, successfully bringing bagworm silk to market. The first product to feature Minolon was a new line of Ezone tennis rackets from Yonex. By combining Minolon with carbon fiber in the racket shaft, Yonex improved vibration control by 5.8% compared to their previous models.

“Bagworm silk is biodegradable and protein-based,” said Asanuma. “Since it’s not made from fossil fuels, it won’t turn into harmful microplastics after disposal. While we currently combine it with plastics, we aim to eventually pair it with bioplastics for an even more sustainable product.”

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide