Nonwovenn enhances activated carbon fabric technology

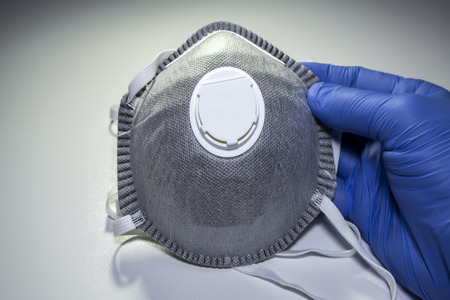

YarnsandFibers News Bureau 2025-11-26 16:07:06 – United KingdomNonwovenn, a global leader in nonwoven fabric technology, has announced major improvements in its activated carbon (AC) fabric technology, making it more accessible, efficient and reliable across its certified face mask range.

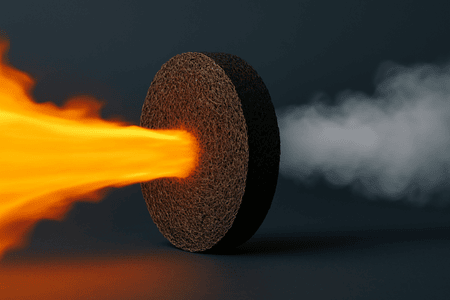

These new upgrades focus on refining processing systems that increase the effectiveness of AC within the fabric, leading to better filtration performance, improved manufacturing consistency and greater product value.

With these enhanced processes, Nonwovenn has improved the way activated carbon is positioned and revealed within the mask layers, ensuring strong adsorption efficiency and extended product life. The company has also improved bonding and lamination methods, controlled AC and fiber distribution more precisely, and upgraded layer design.

“We are always working on new ways to make our activated carbon systems more effective and easier to use,” said Ross Ward, carbontech business director at Nonwovenn. “By refining how AC is embedded and exposed in our fabrics, we are seeing clear improvements in performance and process stability, which increases customer value and product competitiveness.”

Nonwovenn’s certified mask fabrics comply with established standards, including EN 149 for particle-filtering half masks under the European PPE Regulation, as well as relevant medical device standards when required. These products offer dependable protection and traceability for both workplace and clinical settings.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide