Everbloom redefines supply chains with protein-based fibers

YarnsandFibers News Bureau 2025-08-21 17:08:35 – USATextile entrepreneur Simardev Gulati and polymer scientist Michael Jaffe have launched Everbloom, a supply chain and next-generation material designed with circularity at its core. “We’re not just creating a new fiber,” said Gulati, co-founder and CEO of Everbloom and Bloom Labs. “We’re reshaping the supply chain to focus on regeneration instead of extraction and waste.”

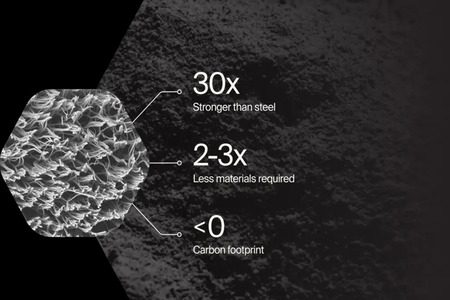

The startup is developing protein-based fibers by transforming waste streams, especially keratin, into high-performance materials. By using discarded proteins from existing supply chains, Everbloom is working toward local, U.S.-based fiber production with better economics and climate impact. Through its patented protein melt-spinning technology, Everbloom converts pre-consumer textile waste into high-performance yarns.

The collaboration ensures that Everbloom can refine its materials quickly while maintaining consistent quality. “Mills need a reason to adopt new materials, is it cost-effective, does it fit their business? That’s why we wanted a partner with expertise in proteins and a strong scientific approach,” Gulati added.

According to a Life Cycle Assessment, Everbloom fibers use up to 99 percent less water and land compared to traditional materials, while cutting greenhouse gas emissions by as much as 80 percent, all without sacrificing softness, durability, or thermal performance.

Looking ahead, Everbloom’s next step is to introduce its fibers through collaborations with high-end brands. “It depends on how confident we are in the quality, and it’s always a joint process with the brands,” Gulati said. “But we’re on the right track, and hopefully it will happen sooner rather than later.”

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide