Epic Group to use heat pumps for carbon-free apparel production

YarnsandFibers News Bureau 2025-11-18 15:56:03 – IndiaSustainable fashion company Epic Group has taken a major step toward carbon-free manufacturing by installing high-temperature industrial heat pumps at its garment production facility in Bhubaneswar, India. This initiative marks an important milestone in moving the fashion industry toward cleaner, carbon-free manufacturing methods.

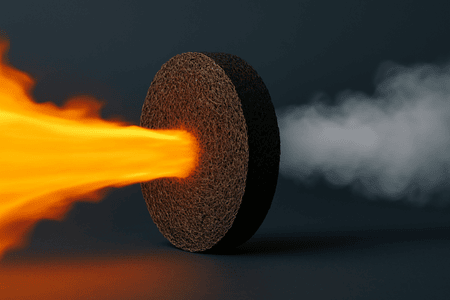

Epic Group is now using heat pumps that rely on refrigerants to transfer heat. These systems work somewhat like air conditioners but operate in the opposite direction. Heat pumps are considered one of the most efficient electric heating options, often delivering two or more units of heat for every unit of electricity used.

However, standard heat pumps usually produce hot water at around 90°C, which is not hot enough for industrial dryers that depend on pressurised steam above 150°C. To solve this issue, TRIGeN Decarbonisation, an Indian deep-tech startup, has created advanced heat pumps that can generate pressurised hot water at 135°C to support Epic Group’s laundry processes.

Italian machinery maker Tonello has modified its industrial dryers to run with pressurised hot water at 130°C, allowing seamless use with the new heat pump systems. These heat pumps also produce cooling as a secondary benefit. Epic Group uses this cooling inside its laundry areas to keep working conditions safe and comfortable, even during extremely hot weather.

Epic Group has funded a pilot project to better understand how the heat pumps perform and to study the related capital and operating costs. The company said that this pilot is expected to reduce 12,500 metric tonnes of CO₂ emissions over its lifetime.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide