EPFL researchers create high-strength smart fabric

YarnsandFibers News Bureau 2026-02-16 14:05:06 – SwitzerlandResearchers at École Polytechnique Fédérale de Lausanne (EPFL) in Switzerland have developed a lightweight textile that can lift more than 400 times its own weight. The breakthrough supports the development of wearable systems that can assist body movement without adding heavy mechanical parts.

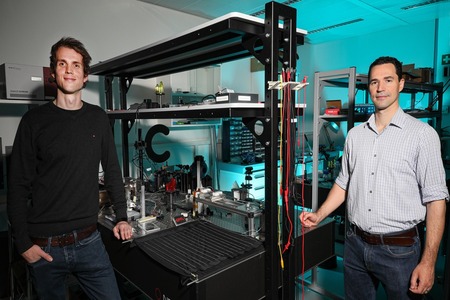

The research team at the Soft Transducers Lab (LMTS) within EPFL’s School of Engineering created textile actuators using shape memory alloy (SMA) fibres arranged in a precise X-crossing pattern. When the fibres contract by 50 percent, a fabric sample weighing just 4.5 grams can lift up to 1 kilogram. The study, led by Huapeng Zhang and LMTS head Herbert Shea, was published in the journal Science Advances.

The technology works through thin SMA fibres made from a nickel-titanium alloy that shorten and become stiffer when heated by an electric current. Although SMA fibres are known for their strength, their performance in textiles has previously been limited by traditional knitting or knotting methods. In those structures, fibres pull in different directions during contraction, causing some of the force to cancel out.

To solve this, the EPFL team designed the X-crossing architecture, where each fibre intersection is carefully aligned with the intended direction of movement. This ensures the fibres work together instead of opposing each other. Along with increasing force output, the design allows the fabric to stretch up to 160 percent of its original length, making the material flexible and easy to wear.

To demonstrate real-world use, the researchers built two wearable prototypes. In the first, the textile was fitted onto a mannequin’s arm as an assistive sleeve for elbow movement. The actuator smoothly lifted a 1-kilogram weight through a 30-degree motion range. In the second test, the fabric was used for on-body compression, showing potential for medical sleeves and performance sportswear.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide