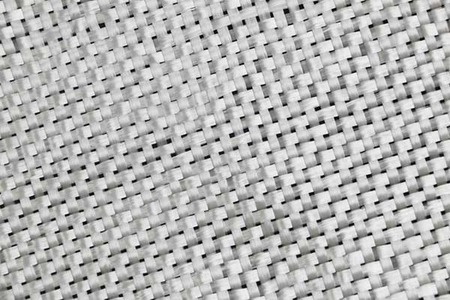

BRM showcases advanced webbing solutions for parachute applications

YarnsandFibers News Bureau 2025-12-30 15:51:33 – USABally Ribbon Mills (BRM), a specialist in designing and manufacturing of engineered woven fabrics, has highlighted its advanced webbing solutions developed for the parachute industry. Known for its focus on quality and innovation, the company designs its webbing to meet the strict performance, strength, and durability requirements of both aerospace and commercial parachute use.

BRM’s parachute webbing is produced using high-performance fibres such as Nylon, Kevlar, Vectran, PTFE, and Zylon PBO. These materials offer high strength, an excellent strength-to-weight ratio, and dependable performance. The webbing is manufactured in line with demanding military standards, including PIA-Spec and Mil-Spec requirements, making it suitable for life-support systems. BRM’s Nylon Webbing (Mil-W-4088K) and Tubular Nylon Webbing (Mil-W-5625K) comply with the Berry Amendment and are thoroughly tested to meet the strict standards required for parachute applications.

The company is also working on new woven tapes and webbings made with DuPont’s Kevlar EXO, a next-generation fiber that provides a higher strength-to-weight ratio than Kevlar® 29 and Vectran. This fiber offers improved performance while being more cost-effective than traditional PBO materials. Kevlar EXO is currently being evaluated for parachute use and is seen as a strong option for applications that require lightweight materials without compromising on strength and reliability.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide