Lenzing, KARL MAYER showcase warp knitting innovation with TENCEL fibers

YarnsandFibers News Bureau 2026-02-04 15:20:08 – FranceThe Lenzing Group has partnered with KARL MAYER to present a new innovation project at Premiere Vision in Paris. The project focuses on developing improved processing methods for Lenzing’s TENCEL Lyocell and Modal fibers using Micro Technology. The project aims to demonstrate how these fibers can be efficiently processed on warp knitting machines while proving their suitability for premium textile products.

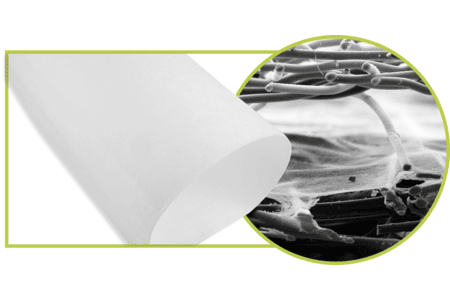

During the project, the teams focused on developing yarns with low hairiness and a uniform cross-section. Reduced hairiness helps prevent fiber lint and contamination during the warp knitting process. At the same time, a uniform yarn structure ensures the required strength to handle thousands of threads at high machine speeds. Four types of yarns were tested, created from two fiber materials and two spinning techniques.

The prepared yarns were warped under strict quality control, especially to reduce lint formation, and were processed using high-performance warp knitting machines. The tests produced three different fabric types for apparel applications. These included an open three-stitch tulle net fabric, a close-knit fabric created using counter-lapped open tricot construction, and a dense surface fabric made using counter-lapped atlas construction.

The outcomes of this project will be introduced to the textile industry at Premiere Vision Paris from February 3 to 5. The partners will also present a capsule collection featuring applications in lingerie, innerwear, and lifestyle garments designed for everyday use.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide