HandMadeStone, CleanKore to advance denim production

YarnsandFibers News Bureau 2025-12-05 16:06:41 – USAHandMadeStone (HMS) and CleanKore have formed a strategic partnership to promote sustainable practices throughout denim manufacturing, from fibre production to final finishing. The collaboration aims to combine CleanKore’s patented low-impact dyeing technology with HMS’ sludge-free washing and finishing method. Together, the companies plan to run a pilot programme to introduce a “fully integrated, planet-positive solution” to global markets.

CleanKore’s dyeing process removes the need for Potassium Permanganate (PP) and reduces water, chemical and energy use across the supply chain. It also controls dye penetration while keeping the fabric’s performance intact.

HMS CEO and founder Beyza Baykan said the partnership unites two strong innovation leaders. CleanKore is improving sustainability at the start of the denim process, while HMS is improving sustainability at the end. Together, their combined technologies and shared vision can help the denim industry lower its environmental footprint while also saving time and costs.

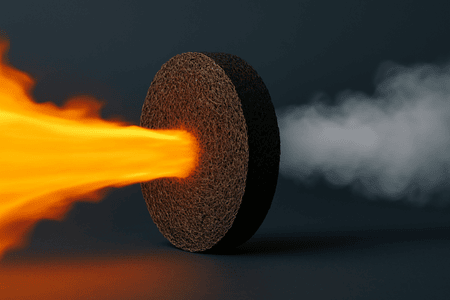

HMS offers composite washing stones that replace pumice stones and traditional washing chemicals. This eliminates sludge generation, reduces water use and ensures more consistent results in finished textiles.

By bringing these technologies together, mills and laundries will be able to lessen their environmental impact from the dyeing stage all the way through garment washing.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide