YKK focuses on circularity in latest annual report

YarnsandFibers News Bureau 2025-12-01 17:25:28 – JapanYKK is placing circularity and decarbonization at the center of its business strategy. The Japanese fastenings company released its new integrated report last week, highlighting its achievements in FY2024 and plans for FY2025.

In the report, YKK said that despite challenges such as global inflation, slow economic growth in Europe and China, and uncertainty caused by political changes in the U.S., its fastening business performed well. Strong customer support and better on-time delivery helped maintain steady sales, especially in ISAMEA, ASEAN, and China.

FY2024 sustainability achievements included receiving approval under the SBTi Net-Zero Standard, recognition from the CDP Climate Change Program, and making sustainability-related investments worth $53 million. The company also updated its 2050 sustainability plan in August, adding new targets to accelerate progress in biodiversity and circularity.

YKK said it is investing actively in efficiency, sustainability and digital transformation to stay competitive and achieve long-term growth.

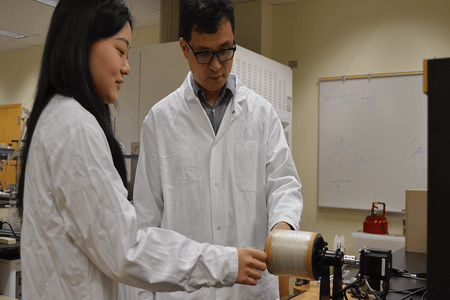

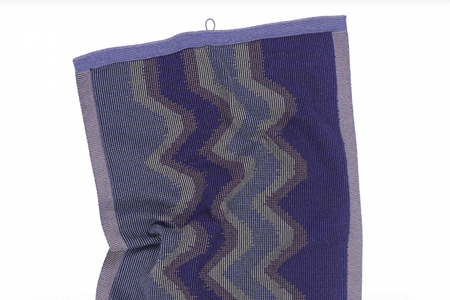

In FY2024, YKK increased the use of sustainable materials to 48 percent, a 10-point rise from the previous year. The company introduced repairable parts, expanded its Natulon Plus product range to support garment-to-garment recycling, and began in-house recycling trials for copper and zinc alloys used in zippers at its Kurobe plant.

The company reported a 57 percent reduction in Scope 1 and 2 emissions compared to FY2018 levels and a 14.4 percent reduction in Scope 3 emissions. YKK also shifted 45 of its global locations to renewable energy and added more solar capacity at seven sites. It further began upgrading equipment to phase out coal-fired boilers and cut down on fossil fuel use.

YKK lowered its total water intake by 7.5 percent compared to FY2018, though its water intensity rose 3.2 percent year-on-year. This increase was mainly due to additional water use for environmental measures at the Kurobe Makino plant. The company installed new production and recycling systems at 15 locations to help reduce water use and managed wastewater in line with ZDHC guidelines.

YKK expanded its product range made with AcroPlating, a brass plating technology that removes all harmful substances such as cyanide, chromium and selenium. In FY2024, 27 percent of brass sliders sold were produced using AcroPlating, marking a three-point increase from the previous year.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide