Researchers develop resin-free composites from fabric waste

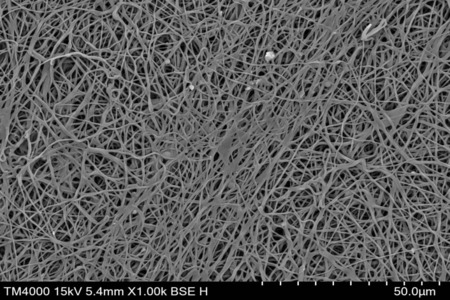

YarnsandFibers News Bureau 2025-08-07 17:10:42 – United KingdomResearchers at the University of Leeds have created an innovative method for producing all-cellulose composites without using any resins, adhesives, or binders. These new composites are formed entirely from fabrics, offering a sustainable alternative to traditional materials.

A key reason for the increased interest in natural fibre composites is the recent development of bio-based resins. These allow for fully natural and sustainable composite products. Now, the University of Leeds has taken this concept a step further by removing the need for resins altogether.

“Our composites are strong, rigid materials that offer a fully natural alternative to traditional natural fibre polymer composites,” said Professor Michael Ries, who leads the Soft Matter Research Group at the university’s School of Physics and Astronomy. “They can be made using virgin, waste, or recycled fabrics. As single-material structures, they are easy to reshape, recycle, and they biodegrade at the end of their use.”

The patented production process doesn’t require chemical modification. It uses only water and an ionic liquid, both of which can be recovered and reused. The final composite material can be shaped in 3D, coloured, patterned, or laser-cut, and also features strong thermal and chemical resistance. The team has already developed a variety of sample composites using different natural fibres with varying properties.

Mike Morris from the University’s Research and Innovation Service explained, “We see a wide range of possible uses for these materials, from interior car panels and sports gear to speaker cones, trays, and decorative tiles. The technology has already gained strong industry interest, and we’re now looking for more partners to explore how this can be scaled up and used in real-world applications.”

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide