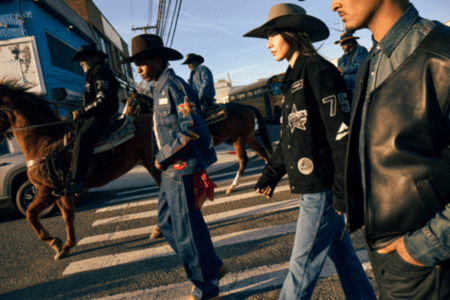

Report sheds light on water usage in indigo dyeing

YarnsandFibers News Bureau 2025-07-23 15:54:09 – USAA recent report by the Transformers Foundation titled “A Reference for Water Consumption During Indigo Dyeing” aims to challenge outdated data and offering clearer insights into the process. The goal of the study was to define, establish, and verify a reliable benchmark for conventional denim warp dyeing.

According to the Foundation, without such a standard, even well-intentioned sustainability efforts can be mistaken for greenwashing. The study revealed that water usage in the pre-dyeing phase is fairly consistent across mills. However, significant differences begin to appear during the post-dyeing stage, specifically in rinsing and washing processes.

While the exact water usage difference between rope and slasher dyeing couldn't be precisely calculated due to machinery variations, experts estimate that rope dyeing requires about 30% more water, as it involves thorough cleaning of the yarn ropes. Operator skill, automation levels, and control systems also contribute to the variation in water consumption.

Importantly, the report does not favor one dyeing method over the other. Instead, it highlights the unique advantages of each. Rope dyeing is ideal for large-scale production thanks to its high efficiency and lower material wastage. On the other hand, slasher dyeing is often more cost-effective, consumes less water, and allows for a broader color range.

The report marks a significant step toward greater transparency in the denim industry, encouraging stakeholders to base sustainability claims on validated, shared benchmarks.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide