Researchers develop technique to recycle mixed polyester waste

YarnsandFibers News Bureau 2025-07-15 15:47:06 – USAScientists have found a new way to break down complex polyester waste such as fibres and textiles into reusable raw materials, without needing to separate them first. These raw materials can then be used again to make high-quality plastic products, helping to support a circular system for polyester use and recycling.

The researchers, whose work was published in the journal Proceedings of the National Academy of Sciences (NAS), said that mixing polyester waste instead of sorting it, which can be expensive or very difficult, might be a better solution for the future.

This new method builds on a process called “enzymatic depolymerisation,” a green technology that uses enzymes, water, and gentle conditions to break polyester down.

So far, enzymatic depolymerisation has worked well in recycling clear and simple PET waste like plastic bottles on a large scale. But it has not been effective for mixed or hard-to-sort waste such as PET fibres, fabrics, or other polyesters like PBT.

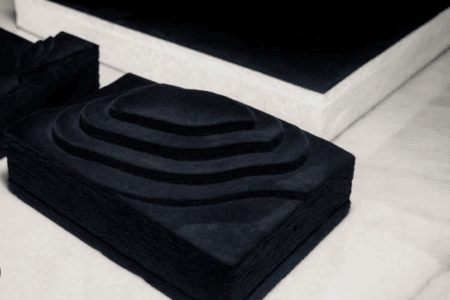

The researchers found that mixing the materials for a longer time and adding a chemical called an epoxy cross-linker made the process more effective, with up to 90% of the material being reused. The team explained that their method can successfully break down hard-to-recycle polyester waste that crystallises quickly, including fabrics made of mixed fibres or filling materials used in jackets and furniture.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide