Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Adasen Trade Compnay

|

Conveying Systems

|

|

|

|

|

micowave tunnel wood dryer--industrial microwave equipment

Machine Dryer Features:

1 Introduction:

Microwave wood drying machine is widely used in wood industry, furniture industry and flooring industry for wood drying. The wood processed through drying is not easy to yield break and deformation, the microwave drying methods has much more advantages, which are heating evenly, short processing time, the level of autoimmunization is high and can produce continuously.

For wood can be heated and dried simultaneously form outer portion to inner portion which can speedup the drying procedure, the dry time in microwave drying method is much shorter than that in any other conventional drying methods.

2 Advantages of microwave wood drying machine:

1, Fast heating. Microwave heating is completely different with traditional heating mode. It makes heating medium become heater, do not need heat transfer process. Although thermal conductivity is poor materials, also can achieve heating temperature in a very short time.

2,Save energy and efficiency. Because materials contain water absorb microwave easily and fever, so in addition to a small amount of transmission loss outside, almost no other loss, so high thermal efficiency, save energy.

3, Heating even,wood processed is not easy to yield break and deformation

. No matter how shape of each part of the body, microwave heating all can make the object and evenly infiltration and electromagnetic wave list to produce the heat. So heating good uniformity, won't appear the endogenous phenomenon focal.

4, Mouldproof, sterilization, fresh. Microwave heating has thermal and biological effect, can sterilize and mould proof in low temperature. Due to heating rapidly, the time is short, can maximum limit save material activity and the vitamin original colour and lustre and nutrition of food.

5, Craft is advanced, control easily. Microwave heating just have the basic conditions of water, electricity, as long as control power, can realize microwave heating or terminate immediately, use microwave equipment can process automation control of

heating process and heating process specification.

6, Covers less area, safety and harmless. Because microwave can be controlled in made of metal heating indoor and wave, so microwave leak is few, no radiation hazards and harmful gases, do not produce the waste heat and dust pollution; Neither polluting food, also do not pollute the environment.

3 Technical parameters:

Power supply

380V±10% 50HZ±1% three-phase five-wire

Microwave Output Frequency

2450±50MHz

Microwave input apparent power

≤70KVA

Microwave output power

≥50KW

Microwave power adjustment range

0-50KW(adjustable)

Ambient temperature

-5-40°C

Relative humidity

≤80%, Surrounding environment:no corrosive gas, conductive dust and explosive gas

Overall dimension(L*W*H)

118100*1440*1750 mm

Transmission speed

0-10m/min(adjustable)

Height of the inlet and outlet

60 mm

Microwave leak

accord with a country GB10436-89 standards(<5 mw/cm^2)

Equipment safety

accord with GB-5226Electrical safety standard

accord with a country GB16798-1997 Food machinery health security index

|

|

|

Adasen Trade Compnay

|

Conveying Systems

|

|

|

|

|

Industrial Tunnel Conveyor Belt Microwave Drying Sterilization Machine for Cocoa Powder Features:

1.Application of cocoa powder sterilizing machine:

Mainly used in the chicken, beef, pork flavor,egg powder, yeast extract, condiments, spices ( pepper, rice flour seasoning flavoring compound; Wang Lucai; five spice powder; king; black pepper;fennel, food additives, flavor powder, seafood, spices ( kelp, seaweed, fish, shrimp, crab ), heating, drying and sterilization process;Also applies to pepper, chili powder, Cara crumb.

2.Microwave drying features of cocoa power processing machine:

Short drying time, strong flavor of the product; low drying temperature, uniform, bright color of products; selective heating.Because water molecules absorb microwave best, so the high water content, absorb microwave power more than the lower part.This is a selective heating characteristics, the use of this characteristic can be done evenly heating and uniform drying; drying moisture direction from the inside to the outside.So, microwave drying has puffing effect , have a great help for subsequent crushing ; save energy and efficient.

3.Microwave sterilizing features of cocoa powder sterilizing machine :

Time is short, fast: conventional thermal sterilization heat from the surface to the interior of the food by conduction, convection or radiation. To achieve sterilization temperature, need longer time usually.Microwave sterilization is microwave energy and food and bacteria and other microbes interact directly, the thermal effect and the non thermal effects interact, to achieve rapid heating sterilization, processing time is greatly shortened, the bactericidal action of various materials is 3-5 minutes.Low temperature sterilization maintain nutrition and traditional flavor, microwave food sterilization equipment can replace steam sterilizing device, which can effectively reduce the material sterilization temperature, generally only about 80 degrees, only 3-5 minutes to achieve complete sterilization, reach preservation and prolong the shelf-life of the role.And equipment fully compliance with the food industry QS certification standards.,we also have CE certificate. Safety, health, environmental protection is the main characteristics. And it can effectively reduce the area and saving cost.

Microwave drying sterilization drying time is short, strong fragrance products, uniform, bright color; has expanded by microwave drying effect on the subsequent smash much help. Microwave is a direct function of the materials were, without intermediate conversion of other links which no additional heat loss, and the corresponding air furnace will not heat the container, so the high thermal efficiency, the production environment is significantly improved compared with the far-infrared heat Can save more than 30%. Easy to control, advanced technology.

Compared with the conventional method, which means that the use of equipment; no thermal inertia, operational flexibility; microwave power adjustable, the transmission speed is adjustable. In the microwave heating and drying, sterilization, no waste water, no gas and other produce, is a safe and sound tech. Improve product quality, economic benefits. The working environment and equipment, low temperature, noise, greatly improved the working conditions, but also saves floor space, and easy removal. Low-temperature sterilization to maintain nutrition and traditional flavor. Microwave sterilization is through to be special and non-thermal effects of heat sterilization, compared with the conventional heat sterilization can be at a relatively low temperature and shorter time to obtain the necessary disinfection and sterilization effect. Practice shows that the sterilization temperature is generally 75 ~ 80 °C will be able to achieve the desired effect, in addition, microwave processing of food to retain more nutrients and color, smell, taste, shape and other flavors, and there is puffed effect. Such as conventional thermal processing of vegetables to retain the vitamin C is 46% to 50%, while the microwave treatment is 60% to 90%; conventional heating liver vitamin A retention was 58%, while the microwave heating is 84%.

4.Technical parameters of cocoa powder sterilization machine:

Power supply

380V±10% 50HZ±1% three-phase five-wire

Microwave Output Frequency

2450±50MHz

Microwave input apparent power

≤28KVA

Microwave output power

≥20KW

Microwave power adjustment range

0-30KW(adjustable)

Ambient temperature

-5-40°C

Relative humidity

≤80%, Surrounding environment:no corrosive gas, conductive dust and explosive gas

Overall dimension(L*W*H)

9550*840*1750 mm

Transmission speed

0-10m/min(adjustable)

Height of the inlet and outlet

60 mm

Microwave leak

accord with a country GB10436-89 standards(<5 mw/cm^2)

Equipment safety

accord with GB-5226Electrical safety standard

accord with a country GB16798-1997 Food machinery health security index

NOTE:

height of inlet&outlet,belt width,machine dimension all can be designed according to your requirements!

|

|

|

Adasen Trade Compnay

|

Conveying Systems

|

|

|

|

|

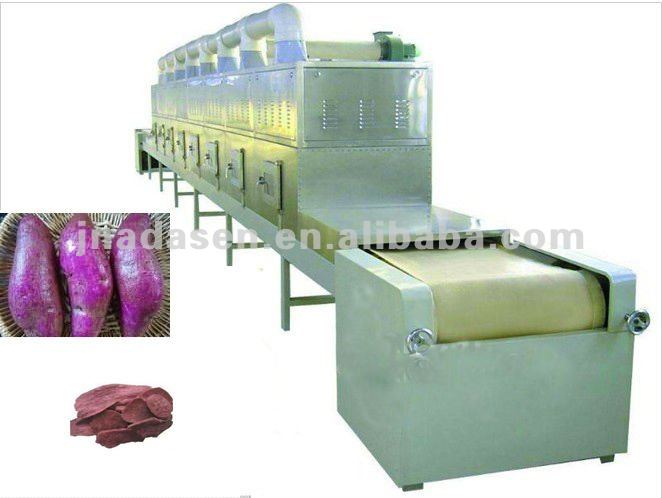

high efficiency microwave vegetable dryer&sterilizer

vegetable industrial microwave dehydration&sterilization machine

1,fast drying machine

2,low energy cost

3,safe and clean

FEATURES:

1, Fast heating. Microwave heating is completely different with traditional heating mode. It makes heating medium become heater, do not need heat transfer process. Although thermal conductivity is poor materials, also can achieve heating temperature in a very short time.

2,Save energy and efficiency. Because materials contain water absorb microwave easily and fever, so in addition to a small amount of transmission loss outside, almost no other loss, so high thermal efficiency, save energy.

3, Heating even. No matter how shape of each part of the body, microwave heating all can make the object and evenly infiltration and electromagnetic wave list to produce the heat. So heating good uniformity, won't appear the endogenous phenomenon focal.

4, Mouldproof, sterilization, fresh. Microwave heating has thermal and biological effect, can sterilize and mould proof in low temperature. Due to heating rapidly, the time is short, can maximum limit save material activity and the vitamin original colour and lustre and nutrition of food.

5, Craft is advanced, control easily. Microwave heating just have the basic conditions of water, electricity, as long as control power, can realize microwave heating or terminate immediately, use microwave equipment can process automation control of heating process and heating process specification.

6, Covers less area, safety and harmless. Because microwave can be controlled in made of metal heating indoor and wave, so microwave leak is few, no radiation hazards and harmful gases, do not produce the waste heat and dust pollution; Neither polluting food, also do not pollute the environment.

From the economic efficiency analysis, microwave drying also have advantages than traditional methods , such as compared with the far infrared drying, usually save energy more than a third.

In actual work,microwave dry and sterilization equipment basically use in material with low moisture (moisture content below 30%). Also can be used for high moisture.At this time, traditional drying method (hot air, electric oven d )drying rate low, consume energy , and tunnel type microwave drying equipment from start to finish drying ,need three to five minutes. Traditional methods, equipment, covering a large area, many employees, often have the pollution, fire control, etc

|

|

|

Adasen Trade Compnay

|

Conveying Systems

|

|

|

|

|

Continuous tunnel microwave sterilizing&drying machine for paper products

Specifications

This kind of microwave equipment mainly use in drying and mould proof for paper, cardboard, the honeycomb paperboard

This kind of microwave equipment mainly use in drying and mould proof for paper, cardboard, pulp, the honeycomb paperboard and corrugated board

The advantage of microwave drying paper equipment:

1, the drying and moulding quality is quite good and cannot be cracked.

2, Easy to control and operate. It can control the heating and drying time automatically.

3, Saving time and high production.

4, Energy consuming little

5, Production intensity and space is little

6, Saving labour and procedure, especially it's easy to connect automatically with before and after procedure. And reduce and carring time.

7, Clean and protecting environment. No pollution and cannot bring "three wastes" question

|

|

|

Adasen Trade Compnay

|

Conveying Systems

|

|

|

|

|

Specifications

1.excellent quality

2.save energy

3.cover less area

4.keep original nutrition,taste

high quality and low price tunnel drying and roasting machine for fruits

Detailed Product Description

High product quality

Time and energy saving

Rapid heating rates

Considerably reduced processing time and temperature

The application of microwave tunnel drying machine for fruits:

It is for drying and sterilizing medicinal materials and pills and for drying and sterilizing and heating materials in strip shape, cube shape,small&round shape, powdery form as well as filter cake which have high water content and certain viscosity. It is also used for sterilizing medicinal liquid before and after the liquid is packaged.

Equipment characteristics

It deals with the problems which can not be solved in the traditional technology. Rise of the temperature and speed of handing materials are fast to improve the essiciency.It can sterilize the materials in low temperature without destroying the effective composition in the medicine. And it can heat the medicine by entreating the package to improve

|