Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

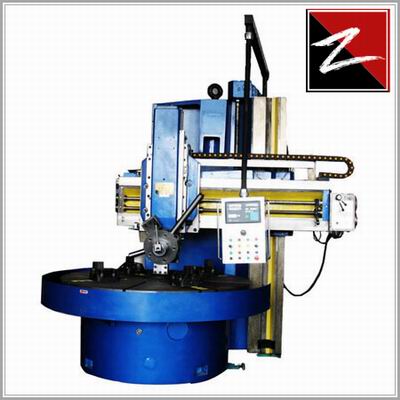

C5112E Single Column Vertical Lathe Machine

Single column vertical lathe

This type of vertical lathe with the Super-premium quality is famous in domestic market.

The beam guide and ram guide are handled by supersonic frequency induction hardening(HRC≥50)while the sliding surface of guide is treated with sticking plastic(including inclined veneers and pressure plate).The precision of the product can be maintained for a ling time and the cycle for heavy repair can be extended more than 10years.

Premium casting (all is HT300) is adopted in lathe, and the artificial heat ageing is carried out. The casting can never be carried out with weight-reducing treatment, the weight of the whole machine accords with the standard one.

Five –angle tool carrier adopts high-precision rat fear for positioning and for all 120 pieces, super-strong stiffness.

4 axial digital displays is taken as the standard confirmation. The electrics adopt Japan Omron PLC control and the electric components utilize the components with ultra-high quality, specification (CE standard) assembly process, in addition, the electrics of the whole machine own super-high reliability. Electric rotary valve, Grade 16 machinery variable aped makes the device convenient, smart and reliable. High-precision gear grinding gear and gear grinding spiral bevel (Grade 6 precision)are featured with low noise and stable operation.

JB/T4116-96 precision test standard of vertical lathe is performed.JB/3665-95 technical condition of vertical lathe is performed.

Accessory configuration is complete and only the user prepares for the knife and measuring tool, the operation can be started immediately. Best after-sale service (pre-sale, sale, after-sale, installation, debugging, training and guarantee)

Optional configuration: rolling working platform, Germany Mecano button station, heightening lathe and prolonging ram and square ram etc.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

C5116E Single Column Vertical Lathe Machine

Single column vertical lathes

This type of vertical lathe with the Super-premium quality is famous in domestic market.

The beam guide and ram guide are handled by supersonic frequency induction hardening(HRC≥50)while the sliding surface of guide is treated with sticking plastic(including inclined veneers and pressure plate).The precision of the product can be maintained for a ling time and the cycle for heavy repair can be extended more than 10years.

Premium casting (all is HT300) is adopted in lathe, and the artificial heat ageing is carried out. The casting can never be carried out with weight-reducing treatment, the weight of the whole machine accords with the standard one.

Five –angle tool carrier adopts high-precision rat fear for positioning and for all 120 pieces, super-strong stiffness.

4 axial digital displays is taken as the standard confirmation. The electrics adopt Japan Omron PLC control and the electric components utilize the components with ultra-high quality, specification (CE standard) assembly process, in addition, the electrics of the whole machine own super-high reliability. Electric rotary valve, Grade 16 machinery variable aped makes the device convenient, smart and reliable. High-precision gear grinding gear and gear grinding spiral bevel (Grade 6 precision)are featured with low noise and stable operation.

JB/T4116-96 precision test standard of vertical lathe is performed.JB/3665-95 technical condition of vertical lathe is performed.

Accessory configuration is complete and only the user prepares for the knife and measuring tool, the operation can be started immediately. Best after-sale service (pre-sale, sale, after-sale, installation, debugging, training and guarantee)

Optional configuration: rolling working platform, Germany Mecano button station, heightening lathe and prolonging ram and square ram etc.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

C5123E Single Column Vertical Lathes

Single column vertical lathe

This type of vertical lathe with the Super-premium quality is famous in domestic market.

The beam guide and ram guide are handled by supersonic frequency induction hardening(HRC≥50)while the sliding surface of guide is treated with sticking plastic(including inclined veneers and pressure plate).The precision of the product can be maintained for a ling time and the cycle for heavy repair can be extended more than 10years.

Premium casting (all is HT300) is adopted in lathe, and the artificial heat ageing is carried out. The casting can never be carried out with weight-reducing treatment, the weight of the whole machine accords with the standard one.

Five –angle tool carrier adopts high-precision rat fear for positioning and for all 120 pieces, super-strong stiffness.

4 axial digital display is taken as the standard confirmation. The electrics adopt Japan Omron PLC control and the electric components utilize the components with ultra-high quality, specification (CE standard) assembly process, in addition, the electrics of the whole machine own super-high reliability. Electric rotary valve, Grade 16 machinery variable aped makes the device convenient, smart and reliable. High-precision gear grinding gear and gear grinding spiral bevel (Grade 6 precision)are featured with low noise and stable operation.

JB/T4116-96 precision test standard of vertical lathe is performed.JB/3665-95 technical condition of vertical lathe is performed.

Accessory configuration is complete and only the user prepares for the knife and measuring tool, the operation can be started immediately. Best after-sale service (pre-sale, sale, after-sale, installation, debugging, training and guarantee)

Optional configuration: rolling working platform, Germany Mecano button station, heightening lathe and prolonging ram and square ram etc.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

C5120E Single Column Vertical Lathe Machine

Single column vertical lathe Manufacturer

This type of vertical lathe with the Super-premium quality is famous in domestic market.

The beam guide and ram guide are handled by supersonic frequency induction hardening(HRC≥50)while the sliding surface of guide is treated with sticking plastic(including inclined veneers and pressure plate).The precision of the product can be maintained for a ling time and the cycle for heavy repair can be extended more than 10years.

Premium casting (all is HT300) is adopted in lathe, and the artificial heat ageing is carried out. The casting can never be carried out with weight-reducing treatment, the weight of the whole machine accords with the standard one.

Five –angle tool carrier adopts high-precision rat fear for positioning and for all 120 pieces, super-strong stiffness.

4 axial digital displays is taken as the standard confirmation. The electrics adopt Japan Omron PLC control and the electric components utilize the components with ultra-high quality, specification (CE standard) assembly process, in addition, the electrics of the whole machine own super-high reliability. Electric rotary valve, Grade 16 machinery variable aped makes the device convenient, smart and reliable. High-precision gear grinding gear and gear grinding spiral bevel (Grade 6 precision)are featured with low noise and stable operation.

JB/T4116-96 precision test standard of vertical lathe is performed.JB/3665-95 technical condition of vertical lathe is performed.

Accessory configuration is complete and only the user prepares for the knife and measuring tool, the operation can be started immediately. Best after-sale service (pre-sale, sale, after-sale, installation, debugging, training and guarantee)

Optional configuration: rolling working platform, Germany Mecano button station, heightening lathe and prolonging ram and square ram etc.

|

|

|

Dalian ZHENGHE Machinery Co., Ltd

|

Conveying Systems

|

|

|

|

|

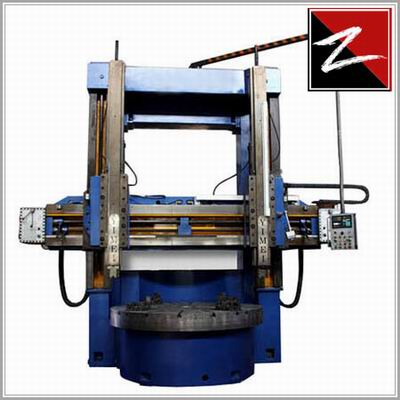

C5228E Double column Vertical Lathes

Double column vertical lathes

The double column adopt modular design, general products, maturity stable and reliable

Premiumcasting (HT300) is handled by heat aging. The beam guide is handled by supersonic frequency induction hardening and it adopts rolling-sliding compound type. The vertical tool holder utilizes square type ram (T600-3),which can realize heavy cutting. The sliding surface uses sticking plastic treatment with durable performance. Manual oil pump lubricates all moveable parts. High quality excellent electrical parts and Japan OMRON PLC control, have the high reliability.

The guide can be divided into two types: dynamic and static pressure and purely static pressure, dynamic pressure can load 10 ton, the purely static pressure can load 16-20tons.

Independent hydraulic station is possessed, which facilitates adjustment, repair and maintenance.

The precision performs JB/T9934.1-1999 precision test of CNC vertical lathe as well as JB/T9934.2-1999 technical condition of CNC vertical lathe.

High-standard processing and assembly process ensure the perfect product quality.

High-precision variable speed gear (Grade 6) and high-precision spiral bevel gear (Grade 6 gear grading) are featured with low noise and high rotary precision.

One year warranty ( installation, debugging and after-sale service )

|