Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Vipeak heavy Industry

|

Chenille Machine

|

|

|

|

|

Also known as vertical roller mill grinding, medium grinding, since the invention has been half a century, with the materials science, development and design of hydraulic technology, the innovation process, so that the body's resistance to vertical grinding mill have been significantly improved and enhanced, more advanced and reliable hydraulic system. Roller roller and disc structure lining the continuous improvement of disc rotation speed corresponding to the grinding fineness of different products to further improve efficiency, so that the development and application of vertical mill to be further expanded. |

|

|

Vipeak heavy Industry

|

Chenille Machine

|

|

|

|

|

Impact crusher product size distribution of the main factors affecting the size distribution of feed, spindle speed and feed rate. In the feed size distribution to determine the circumstances, the basic parameters are the major products with the spindle speed and feed rate of change, therefore, necessary to affect the product particle size distribution analysis of the factors to identify the most important influence factors, the actual production provide the basis for operational control.

|

|

|

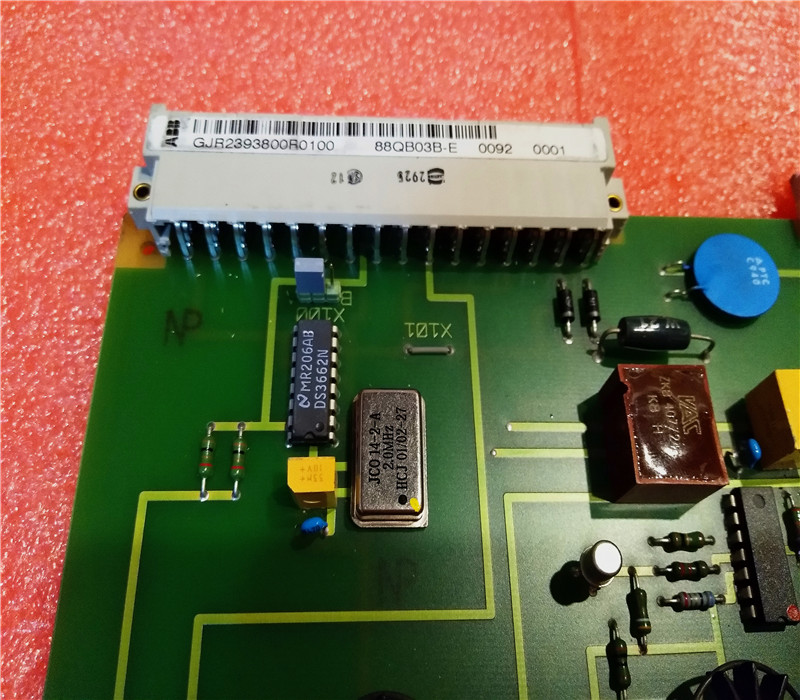

Xiamen Huge Technology Automation Co.,Ltd

|

Chenille Machine

|

|

|

|

|

TRICONEX 3624

Pls add my Skype 8618050017653 , QQ 3340286921 or e-mail me for giving you the best price.

Contact: Tibby Chen

E-mail:[email protected]

Skype: 8618050017653

Call us: +86 18050017653

Q Q : 3340286921

WE CAN PROMISE:

100% Origin goods

In stock

1-year warranty

Timely delivery (1-3working days)

Competitive price.

If there is a quality problem within 15 days, you can return and exchange the products!!!

Our company has been established for many years and become the outstanding one of this field in Xiamen.

We supply large system (DCS/PLC/TSI) spare parts, modules, card pieces.

There are various brands, such as Foxboro, Bently, Westinghouse, ABB, AB, GE, Honeywell, Emerson, Siemens, Schneider, Woodward Yokogawa, Triconex and so on.

Parts of the other models following,

TRICONEX

3604E

3503E

3624

18.11.20

AB

1746-NT8

1746-A13

YOKOGAWA PW702

ABB

CDP312R

SDCS-PIN-3A

ICS

T8461

T8403

ABB SD822 3BSC610038R1

ABB SD822 3BSC610038R1

AB 1746-NT8 AB 1756-BA2 15

Siemens

A1A10000225.00M

A1A10000350.00M

A1A363818.00M

A1A10000423.00M

A1A461D85.00M

A1A10000283.01

A1A10000432.01M

10000092.01

DS3800HSCA

DS3800HRTA1A1B

DS3800HRTA1A1A

DS3800HRRB1D1D

DS3800HRRB1C1B

DS3800HRRB1B1A

DS3800HROA1A1A

DS3800HRDA1C1C

DS3800HPTK1B

DS3800HPRC1A1A

DS3800HPLA1B1D

DS3800HPLA1A1A

ABB DSRF160

ABB DSRF150

ABB DSRF160M

ABB DSRF154M

ABB DSRB310

ABB DSRB110

ABB DSPX3221

ABB DSPC3221

ABB DSPC3122

DSPC3121

DSPC3001

DSPC172H

DSPC172-2

DSPC172

DSPC171

DSPC170H

DSPC170

DSPC157

DSPC155

DSCL110A

DSCA190V

DSCA180B

DSCA130

DSCA125A

DSCA114

DSBC170

DSBC111

DSBC110

DSBB170

DSBB110A

DSBB110

DSAV111

ZT5539A2/Y1

ZT5538a

|

|

|

Collet Automation Equipment Co, Limited.

|

Chenille Machine

|

|

|

|

|

Attention! THERE more cheaper products.

Email:[email protected]

QQ:2428175040

Contact: Ted

Skype:+8618059275924

Whatsapp:+8618059275924

Benefits:

1. lower your support costs

2. Provide on-going availability of automation replacement parts

3. Large number of inventory

4. Support door-to-door?inspection

|

|

|

Vipeak heavy Industry

|

Chennile Machine

|

|

|

|

|

Aggregate classification |