Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

MAHESH TWISTO TECH PVT. LTD.

|

Braiding Machine

|

|

|

|

|

» Rope range

» Pitch Size

» Bobbin Size

» Strand Bobbin Capcity

» Cariar Type

» Braid Length 16 mm to 48 mm (220 MTR or more)

900 mm

Traverse 650 mm X DIA 360 mm

29 kgs

Vertical Bobbin

30 mm to 175 mm

» Horn RPM

» Diamenssion

» Weight of Machine

» Motor Power

24 max

L-5.5 mtr x W-3 mtr x H-4 mtr (Horn asse with Take up)

17,000 Kgs ( Approx.)

10 HP + 2 HP

(Horn asse + Take up)

PRODUCTION CAPACITY ( On 100% Efficiency )

Rope DIA/MM Braid Length/

MM Kgs MTR Prod/Hours

Kgs (100%E) Horn

RPM (Max) Length in MTR

16 51 0.116 4.45 24 2000

20 64 0.181 8.30 24 1281

24 76 0.261 14.30 24 888

28 89 0.355 22.75 24 653

32 102 0.464 28.40 20 500

36 114 0.587 40.00 20 395

40 127 0.725 55.25 20 320

44 140 0.877 73.70 20 264

48 152 1.044 95.20 20 222

KEY FEATURES

» Running Parameters Appear On Display

» Predetermind Length Setting

» Braid Length Adjustment By Electronic Control

» Auto Stop At Empty Bobbin Control

» Stepless Veriable Synchronized Speed Control

» Safety Fancing

» Helical Gear Boxes

Machine Construction

» Horn Gear and Horn falnges are in Steel Matirials

» Single Stage Foundation Base

» Heavy Duty Niddle And Thurst Bearings Are In Horn Assembly

» Verticle Bobbin Mounting Provision

» Hardchrome Plated Guide Pulles

Braiding Strander Machine

» Dia. Range

» Twist range

» Twist per revolution

» Machine RPM

» Main motor power

4 TO 16MM

15 TO 80 TPM

ONE

600 RPM MAX.

10 HP With AC Drive

» Traverse motor

» Take up size

» Take up capacity

» Twist direction

» Diamession

» Weight

2 hp with ac drive

360 mm dia. X 660 mm traverse

150 mm id.

29kgs.

S or Z

L-14' x W-6'4' x H-6'

3000 kgs (approx)

KEY FEATURES

» Auto stop at predetermined length

» Fully faced guard

» TPM change by timming belt pulley

» Stepless veriable speed control

» Distribution plate for yarn distribution

» Door Sensors

» AVM Pads

» Heavy duty pulling capstan

Braiding Coiling Machine

» Model

» Rope Size

» Head Speed

» Coil Size Max

» Motor

» Dimension { H x L x W)

» Weight

MTP / BRCL - 20

16 mm to 48 mm

As per rope feeding

230 kgs.

850 mm traverse x 1000 mm diameter x 150 mm ID

5.0 HP with AC Drive

10'6" x 5'0" x 5'0"

700 kgs. approx.

KEY FEATURES

» Layer To Layer Rope Winding

» Frequently Start Stop For Power Saving

» Online Connected

» Heavy Duty Structure

» Collepsible Head

NOTE

We reserve the right to change details /specifications / equipment without any prior notice.

|

|

|

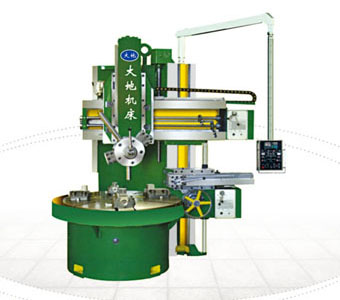

Dalian New Earth Machinery Co.,Ltd

|

Braiding Machine

|

|

|

|

|

The Vertical lathe features

1 The series vertical lathes can be used for mechanical processing such as rough and finishing machining inside and outside the cylinder, inner and outer conical surface, head face, grooving etc.

2 The main shaft of workbench is centered by the high precision and adiustable diametral clearance biserial short cylindrical roller bearing. With the constant current and static pressure rack in axial direction. The workbench has the features of high running accuracy, large carrying capacity and small thermal deformation.

3 The pedestal, workbench. lathe body and beam are made of ferrosteel with high strength and high abrasive resistance , tempering treatment, eliminate internal stress and deformation.

4. The guide surfaces of lathe body. beam and ram using accurate grinding,good interface and high precision. Beams with hydraulic two-spot locking, feeding is large, without tremble.

5. Vertical tool rest has three forms, Square ram, electric knife tool carrier. and manually pentagon knife tool carrier. Side tool posts are equipped with square tool carrier, Both of tool carriers have balanced with hydraulic pressure.

6 The main shaft of the lathe is driven by AC motor. With the 16 step speed changing mechanism to the main shaft. Achieved the workbench rotate speed range.

7 Additional accessories for digital displaying ,electric grinding head and turning tapering can be provided according to customer’s requirements.

Vertical lathe factory: Dalian New Earth Machinery Co.,Ltd, It is one of the largest vertical lathe manufacturer in China, the main products: conventional vertical lathes, CNC vertical lathes, CNC High-speed vertical lathe, Vertical turning Machines, China vertical lathe and so on.

|

|

|

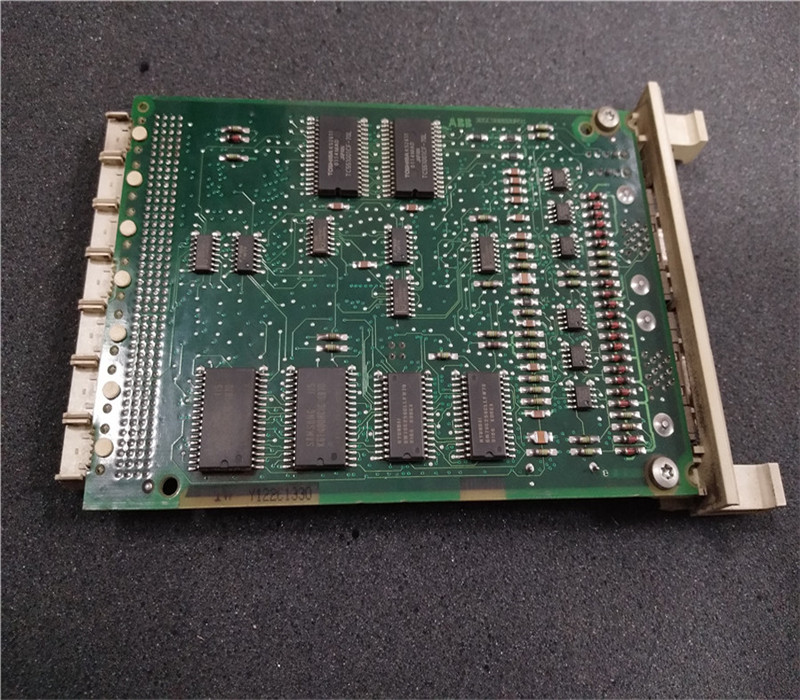

Xiamen Huge Technology Automation Co.,Ltd

|

Braiding Machine

|

|

|

|

|

ABB 3BSE018283R1

Pls add my Skype 8618050017653 , QQ 3340286921 or e-mail me for giving you the best price.

Contact: Tibby Chen

E-mail:[email protected]

Skype: 8618050017653

Call us: +86 18050017653

Q Q : 3340286921

Our Advantages:

1.100% Origin goods

2.In stock

3. 1-year warranty

4. Timely delivery (1-3working days)

5.Competitive price.

If there is a quality problem within 15 days, you can return and exchange the products!!!

Our company has been established for many years and become the outstanding one of this field in Xiamen.

We supply large system (DCS/PLC/TSI) spare parts, modules, card pieces.

Brands:Foxboro,Bently,Westinghouse,ABB,AB,GE,Honeywell,Emerson,Siemens,Schneider,Woodward,Yokogawa,Triconex and so on

Parts of the other models following,

ABB SPBRC300 BRC300,PHCBRC300 BRC410 PHCBRC400 SPBRC410 SPBRC400 IMCPM02, ABB INNIS21, ABB INNPM12,SPNIS21 SPNPM22 INNPM22, ABB IMMFP12, ABB INICT12, ABB INICT13A PBA20000, ABB INIIT13 SPIIT13, ABB SPDSO14 IMDSO14, ABB IMDSI14 SPDSI22 SPDSI14 SPDSI13 IMDSI22IMDSI14 ABB IMFEC12 SPFEC12, ABB IMASI23 SPASI23,SPASO11IMASO11, SPCIS22 IMCIS22, ABB IMDSM04, SPFCS01 IMFCS01, ABB IMHSS03 SPHSS03, ABB SPSED01SPSET01 SPTKM01 IMSED01, ABB IMSET01, ABB INTKM01, ABB INSEM11 SPSEM11, ABB NFTP01, ABB NKAS01-15, ABB NKHS03-15, ABB NKLS01-10, ABB NKSD01-10, ABB NKST01-10, ABB NKTU01-15, ABB NTAI05, ABB NTAI06, ABB NTCL01, ABB NTCS04, ABB NTDI01, ABB NTHS03, ABB NTMP01, ABB NTST01 ABB PHARPS32000000, ABB PHARPS32200000

SPNPM22 INNPM22 INNPM12 SPNIS21 INNIS21 IMASI23 IMASO11 SPASO11 IMASO11

FOXBORO 0303472- SF0620A412

FOXBORO 0303475- SF0622A211

FOXBORO 0303363D SF0619A997

FOXBORO 0303419B SF0619F427

FOXBORO 0702075B SF0621C313

FOXBORO 1040028A SF0620D775

MSK

627B02TBC1B

127AA-00001B

51A13TCA2BA990

901P P/N 901P-11

629B 629BU5TBFL1B

852B61PCH2GD

225A-26796

65-106645A80

619C12TBFHD

625B23TCEFU

625B23TCEFU

625B23TCEFU

621C01TMFHF

621C-22772

621C13TBFHC

621B02TBFH

621C01TBFHB

628A02TBE

628BX01TBE1B

628A-13476 Siemens 565-2820

Siemens 565-2120

Siemens 560-2820

Siemens 560-2136

Siemens 560-2128A

Siemens 560-2127B

Siemens 560-2126B

Siemens 560-2123

Siemens 560-2122

Siemens 560-2120

Siemens 575-4916

Siemens 575-4366

Siemens 575-4332

Siemens CTI 2560

Siemens CA-2587678-8010

Siemens CA-2587678-8005

Siemens 555-1106

Siemens 555-1105

Siemens 555-1104

Siemens 555-1103

Siemens 555-1102

Siemens 555-1101

Siemens 545-1106

Siemens 545-1105

Siemens 545-1104

Siemens 545-1103

Siemens 545-1102

Siemens 545-1101

Siemens 535-1212

Siemens 525-1104

Siemens 525-1102

Siemens 505/ATM-0440

Siemens 505/ATM-0220

Siemens 505-RTU

Siemens 505-CP5434-L2DP

Bently 3500/50

Bently 3500/45

Bently3500/20

|

|

|

Xiamen ZheXun Electric Automation Co., Ltd

|

Braiding Machine

|

|

|

|

|

HGM series micro powder grinder, which is designed by our engineers and technicians on the basis of multiple innovation, test and experience over two decades, has absorbed many advantages of home and abroad mill manufacturing technique. It has been proved by thousands of customers that our machine has outstanding features and stable quality. Our HGM series micro powder grinder can upgrade its production and the additional value which is suitable for our customer to use. It is the ideal equipment for fine milling.

HGM series micro powder grinder is the equipment specializing in producing fine and superfine powder of non-inflammable, non-explosive and brittle materials with Mohs\'s hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite and vermiculite, sepiolite, attapulgite, rectorite, diatomite, barite, gypsum, alunite, graphite, fluorite, rock phosphate, Kalium ore, pumice, etc., totally more than 100 kinds of materials.

Working Principle of HGM series micro powder grinder:

HGM series micro powder grinder mainly consist of main unit, classifier, powder collector, dust cleaner, blower, muffler, sound-proof room, crusher, bucket elevator, storage hopper, and vibrating feeder.

After crushed by hammer crusher, the large materials become small ones and are sent to storage hopper by elevator, and then evenly sent to the upper distribution plate of the turnplate by vibrating feeder and sloping feeding pipe.

When the HGM series micro powder grinder is at work, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the turnplate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, crushed and grinded by the rollers.

The high-pressure air blower constantly inhales air within the HGM series micro powder grinder and, in turn, the airflow with crushed materials are brought to the classifier whose high-speed impeller will screen the airflow: the unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. Most of the qualified powders will fall and exit from the discharging valve at the bottom; a small proportion of the fine powders, with airflow, moves to the dust cleaner, and clings to the surface of the filter bags. At the same time, the fine powders clinging to the surface fall down by the sudden vibration of the filter bags, which is caused by the instantly ejected high-pressure gas controlled by the pulse valve. The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed. In addition, filtered clean air will be emitted from the air outlet of muffler in the end.

|

|

|

Amikon Limited

|

Braiding Machine

|

|

|

|

|

Minimum order quantity: 1 piece

Type of payment: 100% Payment in Advance

Warranty: one year

Courier partners: DHL, UPS, TNT, FedEx and EMS

Lead time: 2-3 working days

Technical specification, manuals and data sheets: Available on request

To get our best price & fast quotation, pls send us e-mail now.

Contact Us

This is Ricardo.

Email me:[email protected]

Inquiry on Skype: d9c44bac84a891fb

Call me by phone : +8618030132586

Whas APP: +8618030132586

QQ:2851195479

Wechat: 18030132586

About Us

AMIKON LIMITED provides surplus parts to users of installed control systems, drives, and servo motors. We have a knowledgeable staff, extensive test systems, and sophisticated refurbishment capabilities. All of our parts are covered with an industry leading 1-Year Warranty.

The advantage brands and series of our company are as follows:

Control Systems (DCS, PLC/SPS, CNC)

- Panel Controllers

- HMI and Display Panels

- Industrial PC’s

- Drives ( Frequency Inverter and Servo)

- Motors

- Power Supplies

Hot Selling

EMERSON KJ1501X1-BC2

EMERSON KJ3201X1-BA1

EMERSON KJ4001X1-BA3

EMERSON KJ3203X1-BA1

EMERSON KJ3204X1-BA1

EMERSON KJ3241X1-BA1

EMERSON KJ3222X1-BA1

EMERSON KJ2003X1-BB1

EMERSON KJ3202X1-BA1

MYNAH GRW1780273

ABB ABB DSSR 116

ABB DSDI 110

ABB DSDO 115

ABB DSPC 155

ABB DSMB 144

ABB DSCA 114

ABB DSCA 125

ABB DSBC 110

ABB DSAI 110

ABB DSTD 150A

ABB PM864AK01

ABB CI858K01

ABB DO820

ABB DI810

ABB AO820

ABB AI 810

Our advantage:

1.Allen-Bradley 1756/1769/1771/1785 Series

2.ABB 800xA?/Bailey INFI90/DSQC/ Series

3.Bently Nevada 3500/3300 Monitoring System

4.Schneider Series Quantum 140 series ?

5.General electric IC693/IC697/IC698/IS200/DS200 Series

6.SIEMENS MOORE/S5 Series

7.Westinghouse: OVATION/WDPF/MAX1000 system spare parts

8.Invensys Triconex: Redundant fault-tolerant control system, Most modern fault-tolerant controller based on Triple Modular Redundancy (TMR) architecture.

9.Honeywell TDC2000/TDC3000/Experion HS Series

10.YOKOGAWA CS3000 System

Contact Us

This is Ricardo.

Email:[email protected]

Mobile Phone:86-18030132586(WhatsApp, Wechat)

QQ:2851195479

|