Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

shangqiu huahong mechanical and electrical equipment co.,ltd

|

Recycling Line

|

|

|

|

|

Safety:

1. Professional sealing technology for cover, oil outlet.

2. Heavy oil is separated which can avoid the problems of jam in later condensing.

3. Vacuum system will prevent exhaust gas from going back to reactor and causing accident.

4. Alarm, safety valves, pressure gauge and safety valve.

5. It is dangerous to make exhaust gas (C1 to C4). In our process, it is transferred first through the safety device and a safety burning air muzzle. Before burning, we should ensure the safety of production.

Environment friendly:

1. Well water dedusting system with high pressure nozzle and environmental damper inside can avoid black smoke.

2. The exhaust gas will be directly recycled for heating reactor, no gas pollution

3. Every junction of the reactor is in good sealing situation with professional sealing material.

Long service life:

1. Material: Q245R special steel plate, thickness 14mm.

2. The service life of the reactor will be 8 years

Energy saving:

1. Well sealing for heating system, no gas leak and saving fuel.

2. The exhaust gas will be recycled for reactor heating.

|

|

|

shangqiu huahong mechanical and electrical equipment co.,ltd

|

Recycling Line

|

|

|

|

|

Safety:

1. With an auto welding machine for the reactor, it can not only greatly improve working efficiency but also guarantee the quality of welding seam, thus avoid explosion caused by gas leak.

2. Professional heating treatment and x-ray detection chamber are especially for welding.

3. Vacuum system will prevent oil gas from going back to reactor and causing accident.

4. Professional thermometer, pressure gauge and safety valve.

5.It is dangerous to burn exhaust gas(C1 to C4) without any safety measures. In our process, it is transferred first through the safety device and a safety burning air muzzle. Before burning, we should ensure the safety of production.

Environment friendly:

1.Well water dedusting system can avoid black smoke.

2.The exhaust gas will be recycled for heating reactor, no gas pollution

3.Every junction of South America

the reactor is in good sealing situation with professional sealing material.

Long service life:

1.Material: Q245R special steel plate ,thickness 14mm.

2. Welding: Automatic welding machine with heating treatment and x-ray detection will prolong the service life of reactor to the max.

3. The service life of the reactor will be 8 -10 years

Energy saving:

1. Well sealing for heating system , no gas leak and saving fuel.

2. The exhaust gas will be recycled for reactor heating .

3) Technical parameter

|

|

|

shangqiu huahong mechanical and electrical equipment co.,ltd

|

Recycling Line

|

|

|

|

|

whole parts

The whole pyrolysis system is composed by 16 parts,which are reactor,Insulation layer,Desulfurization,deduster,Draft fan,Chimney,Water film cyclone,Condenser,Water tank,Cooling tower(optional),Gas recycle system,Oil tank,Gas separate,Waste gas burner,Furnace,Blower,Carbon black slag system.

The keys of pyrolysis plant are reactor and cooling system.

* Reactor

Reactor directly decides the machine's safety and service life. It is made by welded steel plate. So the quality of welding will have a direct impact on safety and service life. Therefore, we use automatic welding machine, X-rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

|

|

|

shangqiu huahong mechanical and electrical equipment co.,ltd

|

Recycling Line

|

|

|

|

|

Reactor

Reactor directly decides the machine's safety and service life. It is made by welded steel plate. So the quality of welding will have a direct impact on safety and service life. Therefore, we use automatic welding machine, X-rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

Cooling system

For cooling systems, there are three steps. Cooling pipe is the first step. The second is condenser. We have three condensers. And there are 33 pipes in one condenser. Diameter is 45mm for one small pipe. Third is water tank,we considerate the temperature was very high in Summer in some countries. This tank will be a great degree to help cooling all of gas oil cooling to make the oil come up to much more purify. The heat exchanging area is about 13square meters for one condenser. So the total cooling area is about 45 square meters, which will guarantee you a high oil yield.

|

|

|

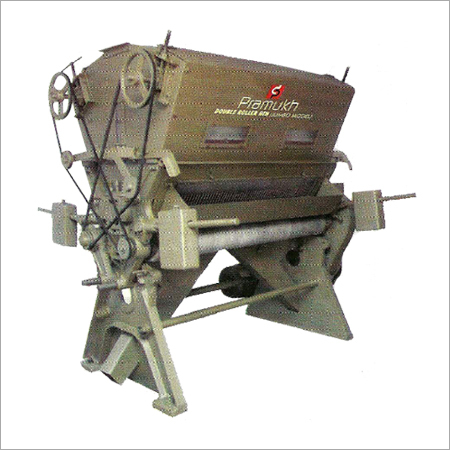

PRAMUKH STEEL INDUSTRIES

|

Recycling Line

|

|

|

|

|

Cotton Gin Machine & Cotton Gin Machinery

Since the founding in 2007 in Gujarat, India, our firm has become the leading organization engaged in offering Cotton Gin Machine & Cotton Gin Machinery which is manufactured under the guidance of trained professionals who adopt rigorous measures to assure quality. This machine is fabricated by our highly qualified professionals using optimum quality components in compliance with international standards. Due to easy maintenance, low noise & vibrations, optimum efficiency and superior performance, offered Cotton Gin Machine & Cotton Gin Machinery is widely demanded in the market. This machine is offered in various specifications and can also be customized on specific needs of the clients.

PRAMUKH DOUBLE ROLLER GIN WITH AUTO FEEDER JUMBO MODEL

More Power Full

Easy To manage

Low Maintenance

High Production Capacity

PRAMUKH DR : FEATURES

Oil Immersed Gear Box Low Friction Minimum wear & Tear, High Durability of Moving Parts and Bearings.

All Gears,Head Pin,Connecting Ros,Beater Arm,Swing Leaver Are Made of High Modularity Ductile Iron.

Low consumption of electric power.

All Parts are provided with bearing to reduce friction for optimum efficiency.

Heavy Duty Helical Gears.High Contact Ratio, Longer Contact between Gears, Wider Gear Teeth, Graducal Teeth Loading,Substantially Less Vibrations, Noiseless Running, Longer working Life, Remarkably Low Consumption of Electric Power.

Very High Performance with minimum Maintenance. Interchangeability of parts.

Lubrication is Pressure fed and Dust Pr off Greasing system.

Oil immersed gear box for long life of gears and bearings.

|