Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Collet Automation Equipment Co, Limited.

|

Packing Machine

|

|

|

|

|

Our company have a lot of successful cases, and my customer repurchase rate is very high.

Contact: Ted Xu

Skype:+8618059275924

QQ:2428175040Phone

No: +8618059275924

Email:[email protected]

Whatsapp:+8618059275924

Warranty: 12 months.Lead time: 1-2 working days.

Type of payment:T/T and Western Union.

Courier partners: DHL, UPS, TNT, FedEx and EMS.

|

|

|

Collet Automation Equipment Co, Limited.

|

Packing Machine

|

|

|

|

|

Our company have a lot of successful cases, and my customer repurchase rate is very high.

Contact: Ted Xu

Skype:+8618059275924

QQ:2428175040Phone

No: +8618059275924

Email:[email protected]

Whatsapp:+8618059275924

Warranty: 12 months.Lead time: 1-2 working days.

Type of payment:T/T and Western Union.

Courier partners: DHL, UPS, TNT, FedEx and EMS.

|

|

|

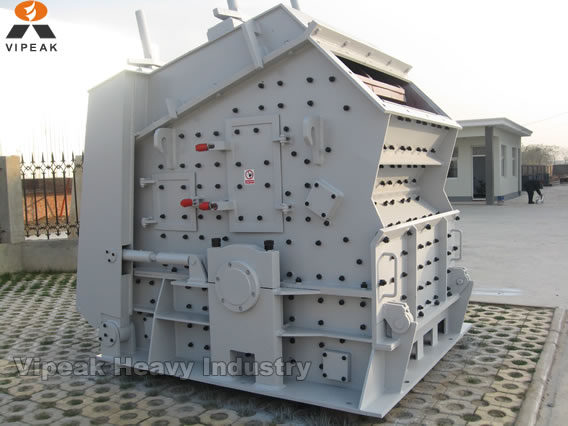

vipeak heavy industry machinery co.,ltd

|

Packing Machine For Yarns And Fabrics

|

|

|

|

|

Impact Crusher is used in both primary and secondary crushing applications of aggregate, and in recycle crushing of reinforced concrete, asphalt and other construction and debris. VIPEAK is a reliable supplier of Impact Crusher with new design. Impact Crusher is composed of rotor, impact rack, frame, ratchet cover device, Transmission Device and other parts.

|

|

|

XingBang Heavy Industry Machinery Co., LTD

|

Packing Machine For Yarns And Fabrics

|

|

|

|

|

Ceramic Ball Mill-cnxb0613

Characteristics of Ceramic Ball Mill:

An equipment for Ceramic factories;

To grind cement clinkers and other materials;

Applied in construction, metallurgy, electricity and chemistry;

The structure is divided into integral type and freestanding type;

The machine runs smoothly and works realiably.

Working Process of Ceramic Ball Mill;-cnxb0613

Through material hollow shaft spiral the material is sent to the first mill chamber, in which there are ladder liner or corrugated linings, with steel balls of different specifications in it. When cylinder rotating, centrifugal force will produce steel ball fall down from a certain height, thus impacting and grinding the materials. After coarse grinding in the first chamber, materials enter into the second chamber through a single diaphragm. In this warehouse with flat lining board and steel balls in it, materials are further grinded.

Working Principle of Ceramic Ball Mill;

Ceramic ball mill is a new energy-saving grinding equipment designed by domestic processing machinery experts after absorbing the newest grinding technology home and abroad. It not only improves the productivity and crushing ration, but also expand the application range. It performs an excellent job in secondary crushing, finely crushing and super finely crushing, from limestone to basalt, from stone production to various ores crushing. It is now a new-generation product in mining construction that can replace spring cone crusher and update general hydraulic cone crusher and an ideal equipment for large-scale stone and mining crushing, having the features of low investment, energy saving, simple structure, easy operation, safety use, realibility, etc and applicable to grinding and mixing general and special materials. Customers can choose suitable model, lining board and medium type according to material proportion, hardness, output as well as other factors.

http://www.china-xingbang.com/10.html

Ball Mill

Rotary Kiln

Jaw Crusher

Stone Crusher

Contact person: Luz Liu

Tel: 0086-371-67996871 0086-371-67996872

E-mail: [email protected]

MSN: [email protected]

WEB: http://www.china-xingbang.com/

|

|

|

Hangzhou Hongbo New Materials Co.,Ltd

|

Packing Machine For Yarns And Fabrics

|

|

|

|

|

"Specifications

1.Detergent grade CMC

2.Samples available

3.Excellent solubility

4.Better water adaptation

5.Beneficial to environment

Main Property:

pH (1% in Water Solution): 6.0 - 12.0

2% Viscosity (Brookfield LVDVE, 25°C, Spindle 1, 60 rpm),cps: 100-300

Degree of Substitution: 0.5-0.7

Purity (on Dry-basis), %: 60.0 min.

Moisture Content, %: 10 .0 max.

Particle Size. %: 99.0 min. pass through 80 mesh (180 micron)

Performance:

Detergent grade CMC, when used in liquid & paste detergent, acts as stabilizing and thickening agent; when used in detergent powder, CMC can effectively prevent washes from becoming contaminated after being washed by synthetic detergent due to the action of static between fomite granule and CMC molecule both of which have minus charges.

Product Name: CMC for Food Grade

Exterior: White or yellowish powder

Packing: 25kg net composite paper-plastic bags or 3-ply kraft paper bags with PE liner

Storage: Kept in a light-proof, dry and cool place

http://www.hongbo-it.com"

|